Brake pads are a wear item and are not covered by most new-car warranties. Pad life depends on variables such as traffic conditions, miles driven, the braking habits of the driver, the wear properties of the friction material in the pads, the size of the pads and rotors, braking temperatures and cooling. It’s difficult to predict when a certain vehicle might need a new set of brake pads. Some OE pads can wear out in as little as 25,000 miles or less while others might last upward of 65,000 miles. Eventually, all pads do wear out and have to be replaced.

Pad replacement is required when the thickness of the friction material is worn down to minimum service specifications. Simply put: Worn-out brakes are unsafe and must be replaced.

With electronic brake balancing on late-model cars, more of the braking effort has been shifted to the rear brakes to reduce overall stopping distances. This means that the rear brakes on many cars now wear at the same rate as the ones up front, or even faster. Even so, many applications now require changing both the front and rear pads when the first brake job is performed.

Replacement brakes come in various grades ranging from inexpensive “economy” pads to standard or OEM-equivalent pads to ultra-premium long-life, high-performance pads. There are different products to meet the needs and expectations of different customers, so it’s important to make sure the replacement pads you recommend are “right” for the application. In recent years, a whole new generation of low-copper and copper-free friction materials have been introduced to comply with legislation that requires reducing the copper content of friction materials for environmental reasons. Copper helps many ceramic and non-asbestos organic brake pads dissipate heat. But it also generates brake dust that can contaminate rivers and lakes near roadways. New rules call for a reduction in copper content by 2021 and beyond.

To comply with the rules, brake manufacturers have been developing new low-copper and copper-free friction formulas for their product lines. Over the past several years, a number of such products have been introduced in the aftermarket. These “next generation” friction materials have turned out to be superior to many existing friction materials in terms of braking performance, wear and noise. So as time goes on, the new pad materials are replacing the older pad formulas materials across a range of product lines. The vehicle manufacturers also are moving full speed ahead on adopting the new low-copper pads rather than waiting for the mandated deadline to draw nearer.

Low-copper pads that meet the law’s requirements are certified by the Automotive Manufacturers Equipment Compliance Agency (AMECA). Ratings include “A,” “B” and “N” edge codes. Those that meet the highest rating “N” contain less than 0.50 percent copper and no asbestos, chromium, lead, mercury, cadmium or antimony. “Leaf Marks” on retail brake pad packaging also are being used to help consumers identify environmentally friendly, low-copper friction materials.

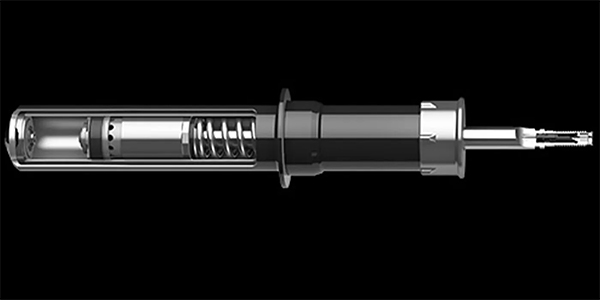

In addition to the ongoing changes in friction materials, one brake supplier recently unveiled some changes to the shape and design of their brake pads that improves cooling and wear resistance significantly. The new design incorporates a series of humps along the top and bottom edges of the pads to create turbulence for better heat dissipation. The pads also have additional slots in the face of the pad to improve cooling and venting. Slots are used on many premium pads to dampen vibrations and noise, and to allow the pads to outgas more easily when they are hot.