Like most other systems on late-model vehicles, charging systems have become smarter and more complex.

Today’s computer-controlled charging systems tailor the charging rate not only to the electrical demands on the battery and alternator, but also to changing driving conditions. That makes diagnosis much more difficult when something goes wrong. Alternators have one of the highest return rates of any repair part – often because of misdiagnosis. Bench testing an alternator on a test stand should verify whether or not its output is within specifications.

If the unit tests bad, your customer needs a replacement alternator. But if the unit tests good, the problem is something else such as a bad voltage regulator, PCM or wiring harness. Loose, corroded or damaged wiring terminals at the back of the alternator are common causes of charging problems. Wiring connectors and terminals may appear to be okay on the outside, but have loose, corroded or broken wires inside.

Other sources of trouble include loose, corroded or damaged battery cables and ground straps, blown fuses in the power center, or a blown fusible link in the wiring. Another source of trouble can be miscommunication or lack of communication between the PCM and alternator or regulator.

You can have a good alternator that is capable of producing the required charging voltage and current, but it may not work properly if it doesn’t communicate properly with the PCM. Another problem that sometimes occurs is that some “economy” reman alternators that are listed to fit a particular application are not totally compatible with the charging system controls. The alternator may bolt right in, but it fails to communicate with the PCM preventing it from charging normally.

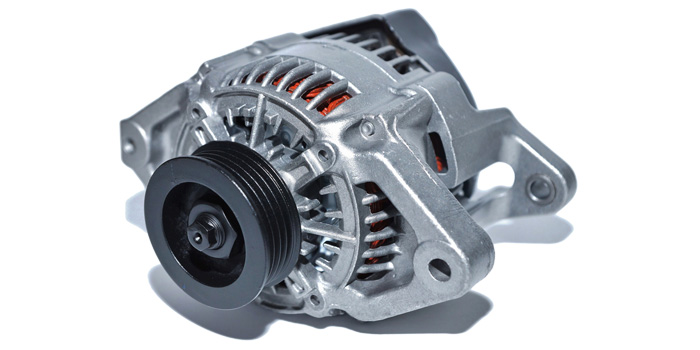

Another item that can affect an alternator’s output is the pulley. Many late-model vehicles do not use a solid alternator pulley. Instead, they have an Overrunning Alternator Pulley (OAP) or an Overrunning Alternator Decoupler Pulley (OAD). An Overrunning Alternator Pulley (OAP) has a one-way clutch mechanism inside the hub that allows the belt to turn the alternator in one direction, but allows the alternator to free-wheel and spin at its own speed when the engine suddenly decelerates.

The pulley should lock up when it is turned one way, but freewheel when it is turned in the opposite direction. If the internal clutch mechanism is bad, the pulley may not drive the alternator, or it may remain locked all the time increasing noise and vibration. An Overrunning Alternator Decoupler (OAD) pulley also has a one-way overrunning clutch inside as well as an internal torsion spring to further dampen vibrations in the belt drive system. The spring acts like a shock absorber to cushion the hub.

This reduces noise at idle and low engine speeds, and helps dampen harmonic vibrations at higher speeds. If the clutch or spring inside the pulley has failed, the pulley may fail to drive the alternator, or it may create vibrations and noise. OAP and OAD pulleys usually thread onto the alternator shaft whereas solid pulleys are typically a straight slip or press fit with a large bolt on the end of the alternator shaft to hold them in place. Some replacement alternators come with pulleys and some do not.

If an alternator with an OAP or OAD pulley is being replaced, and the replacement unit does not come with a pulley already installed, the original pulley can be removed from the old alternator and installed on the new unit – provided it is in good condition. However, on high-mileage vehicles, replacing the original OAP or OAD pulley with a new one is recommended to assure trouble-free operation.