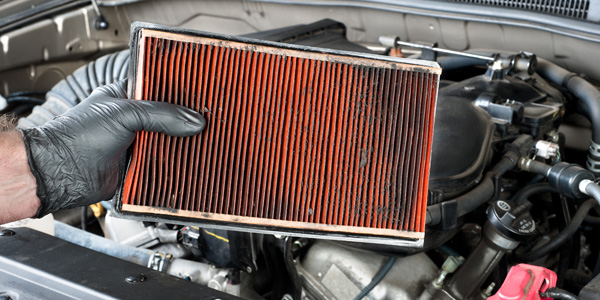

Air filters are a common replacement part, a maintenance item that even the most inexperienced of DIYers are comfortable installing in their own driveway. But for all of the air filters that we sell, we probably only see a small percentage of the old filters across our counter. Other than cross-referencing or measuring the occasional dirty element, we don’t have much opportunity to see the condition of the filter, an advantage that our professional customers enjoy every oil change or other service opportunity.

A dirty air filter can tell us a little about the environment it operates in, the frequency of “regular” maintenance intervals and, sometimes, the condition of the engine itself. A peek into the airbox of a vehicle exhibiting other driveability symptoms also may shed a little light on the true problem.

Oil in the air filter element can be an indicator of PCV or piston ring problems. Blow-by from the crankcase can work its way back through the intake system, being “recycled” along with the crankcase vapors. This oil can cause contamination of the mass air flow (MAF) sensor, and in the case of worn rings, also can contaminate oxygen sensors. If the heated wire element of the MAF sensor becomes coated with oil or carbon deposits, these temperature readings to the PCM may be altered, throwing off the computer’s calculation of air density and therefore fuel requirements. In some MAF designs, the intake air temperature (IAT) sensor also is located in the MAF unit, and oil contamination can throw off IAT sensor values in much the same way.

While proper sensor operation often can be restored by cleaning the hot-wire with special-purpose MAF sensor aerosol cleaners, sometimes the sensor itself must be replaced. When a customer requests a new or remanufactured MAF sensor, you also may suggest inspection and replacement of the air filter element and the PCV valve.

Along with these traditional tune-up items, the tubing and hoses that connect the airbox, PCV, MAF and throttle body can become a source of driveability issues. During throttle-body or MAF service, removal of these hoses can lead to tears, punctures or other sealing issues. Loose clamps or poorly seated hoses can cause unmetered air leaks, leading to erratic sensor readings. Underhood temperatures, fluid and chemical contamination and physical damage can shorten the service life of rubber components. Plastic tubing may become brittle and crack under these same conditions. These leak paths can cause symptoms that aren’t as clear-cut as a failed sensor, or may not reveal themselves through a code scan.

Wiring and electrical connectors can be another source of failure, before and after the diagnosis or service. Mice, squirrels and chipmunks often are discovered as the source of broken wires, but don’t overlook these critters as a potential source of airbox or filter damage. I’ve seen nests built in airboxes, holes chewed through filter elements and once – to my surprise – discovered most of a bag of dry dog food scattered throughout the airbox and engine compartment of a Trailblazer!

In our world of components and pieces, we still need to be aware of the bigger picture. Often, it’s not just one piece or part that solves a customer’s problem, but rather a combination of proper diagnosis, thorough service and quality components. By asking our customers thoughtful, relevant questions, we can build trust, provide effective service and gain repeat business from customers who come back to us for their next repair solution, rather than for repeated trips back and forth to our businesses trying to solve the same problem!