It’s common for a cooling system to develop leaks and drips under normal use. That’s as true now as it was 70 years ago, when Bar’s Leaks created the game-changing chemical formula to stop a radiator leak from within. As with all under-the-hood leaks, it’s important to take action as soon as a coolant leak is detected before it becomes a major problem. At the first sign of leaking coolant or low coolant levels, here are four simple steps to fix your customer’s radiator leak quickly, and get them back on the road.

It’s common for a cooling system to develop leaks and drips under normal use. That’s as true now as it was 70 years ago, when Bar’s Leaks created the game-changing chemical formula to stop a radiator leak from within. As with all under-the-hood leaks, it’s important to take action as soon as a coolant leak is detected before it becomes a major problem. At the first sign of leaking coolant or low coolant levels, here are four simple steps to fix your customer’s radiator leak quickly, and get them back on the road.

1. Inspect the radiator: Do a visual check to spot where the leak is — in the radiator itself, at the radiator tank interface, in the hoses or at the hose connections — to decide how to best address it. Caution: always exercise extreme caution when inspecting a radiator. Coolant can be hot and under pressure, and it can burn your skin or get in your eyes. Wear safety glasses and protective clothing, and always inspect when the engine is cold and turned off.

2. Tighten all connections: Sometimes a coolant leak may simply be the result of a loose or rusted clamp. Where possible, tighten all clamps and replace any that are broken or too rusty to tighten. Also check the radiator cap: the pressure-relief springs can wear out over time and allow coolant to leak under pressure.

3. Perform a coolant flush: A coolant flush will help remove any debris or dirty, gummy coolant in the system that can hide leaks. Flush and re-inspect the radiator for any new leaks. Fresh coolant will also help keep your customer’s engine running at the right temperature.

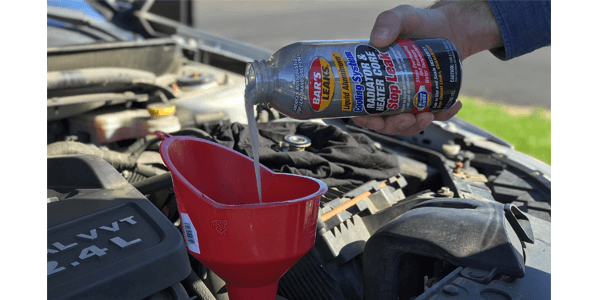

4. Install a proven stop-leak solution: If the leak remains, help your customer choose an appropriate chemical stop leak solution based on the size of the leak and the type of radiator in the vehicle. Bar’s Leaks offers more than a dozen radiator stop-leak products, engineered for the type and nature of the radiator — copper, aluminum, plastic, etc. Most leaks stop immediately after installation. They are easy to use with all types and colors of antifreeze and/or water, andprovide a quick and permanent solution to a radiator coolant leak. Simply follow the directions on the product and in as little as 15 minutes, your customer is back on the road.

“Bar’s Leaks is a brand you can trust,” says Clay Parks, vice president of development for Bar’s Leaks. “We’ve sold millions of cooling system and radiator stop leaks worldwide. Our products are trusted by OEMs, the military, major fleets and generations of car owners. If you have any questions about which product to use, just give us a call. Our technical team in Michigan is happy to help.”

Bar’s Leaks, America’s most trusted stop-leak brand since 1947, offers a full line of chemical repair tools. All Bar’s Leaks products are proudly made in the U.S.A. Based in Holly, Michigan, Bar’s Leaks is an ISO 9001 certified company.

Check out the full line of Bar’s Leaks products in Las Vegas at AAPEX in booth #3616 and at the SEMA Show in South Hall booth #30309. For more information about the full line of Bar’s Leaks stop-leak solutions, visit barsleaks.com or call (844) 445-2233. You can also follow Bar’s Leaks on Twitter at twitter.com/barsleaks, Facebook at facebook.com/barsleaks and through the blog at barsleaks.com/blog.