If a water pump is expected to last 100,000 miles without any issues, that’s about 110 average-size swimming pools one little pump would fill in its lifetime. It’s hard to imagine that a pump could last so long – and many do – but many fail prematurely due to other cooling-system factors.

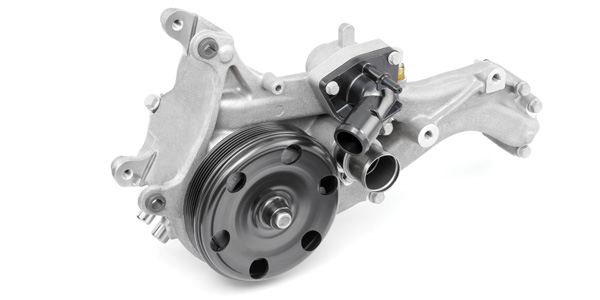

Water pumps can fail prematurely due to corrosion inside the cooling system or from an imbalanced water-pump shaft. If there’s a mechanical fan mounted on the water-pump shaft, vibrations are the result of a bent fan blade, which can lead to the shaft cracking or breaking. A bent pulley also can cause the same damage. Excessive tension on a fan belt or serpentine belt also can overload the water-pump shaft bearings and cause the pump to fail. But in most instances, water pumps fail because of shaft leaks.

Water pumps also can be the victim of cavitation inside the coolant system. The movement of the impeller blades in the coolant can create a flow that generates cavitation. Superheated vapor pressure can occur and eat away the metal. The pump also can generate suction greater than the output and create voids that turn into cavitation, but there are no outward visual signs of cavitation. Typical symptoms of cavitation include overheating and leakage from the weep hole of the pump. The impeller also can separate from the shaft, but you can’t see it until you remove the pump.

Water pumps typically use a unitized seal to support the shaft, along with a ceramic seal to prevent coolant from leaking around the shaft. Sometimes, contaminants that circulate with the coolant are abrasive enough to act against the seal and eventually will cause a failure at the seal. At the first sign of seal wear or coolant leaking around the pump housing or shaft, the pump should be replaced.

The most common water-pump failure is due to worn bearings. Water pumps move a tremendous amount of coolant, and they just simply wear out over time. Belt tensioners can rattle when they’re worn out. You can spin the pump by hand when the belt is loose to feel if the rotation is smooth or notchy. You can check the tensioners with this method as well.

Improper belt tension can bend the impeller shaft. And mixing coolants, or using the wrong coolant, can cause damage to the water-pump seals and bearings, and can lead to the impeller shaft to fail. If the pump is out, look at the impeller for signs of corrosion or cavitation. If the impeller looks corroded, a good coolant flush and refill should take care of it, since the additives probably have broken down.

Worn belts and tensioners can cause a loose belt that may break or pop off. If the belt is too loose, it can slip and not allow the pump to turn as fast as it should, which will lead to the engine overheating. If this happens, it can lead to more problems than just water-pump failure.