Variable Valve Timing Overview

In an effort to increase fuel efficiency and elevate performance across today’s vehicles, nearly every manufacturer has equipped new vehicles with Variable Valve Timing (VVT) technology, also known as Variable Cam Timing (VCT).

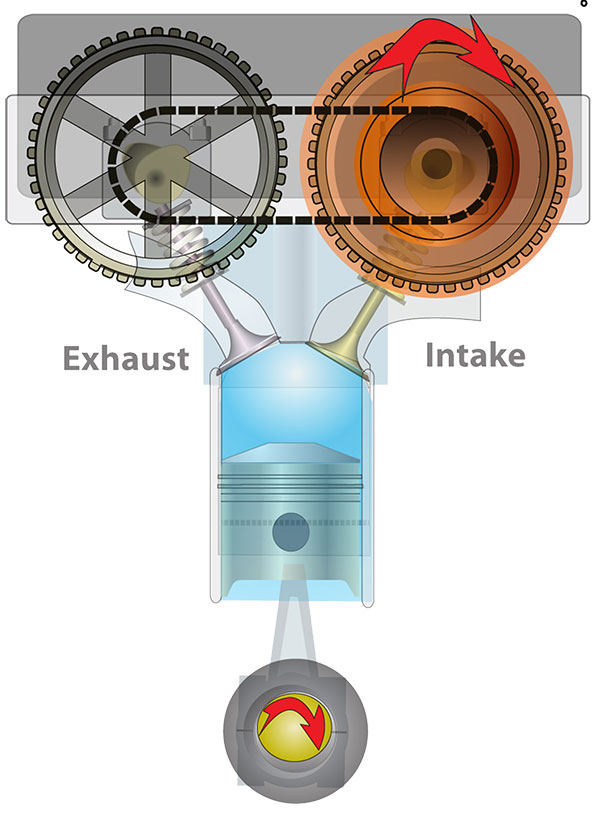

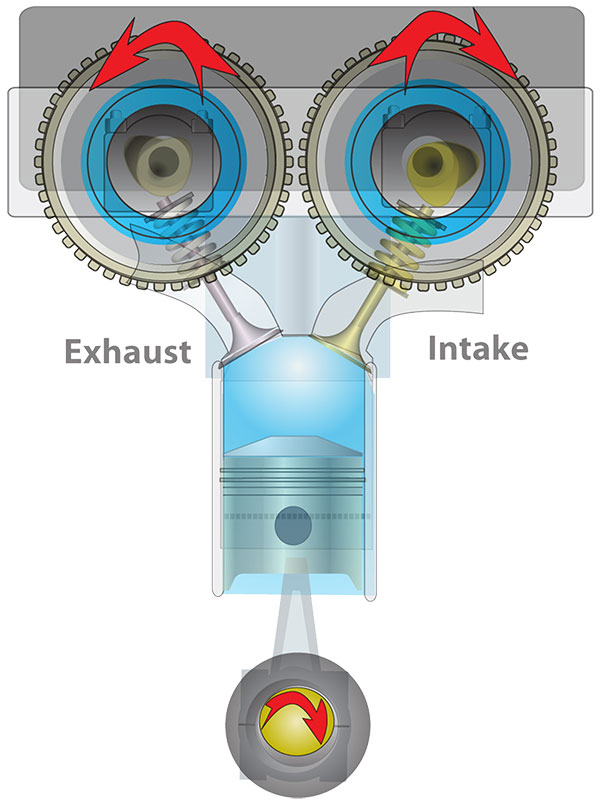

The primary components in a VVT systems are control solenoids and sprockets. These parts, in conjunction with other components including timing chains, drive gear sprockets, crankshaft position wheel, crankshaft seal, and gaskets, make up the VVT system. Most VVT systems are oil-activated, and some newer systems operate off rotational torque from the engine.

How does VVT work?

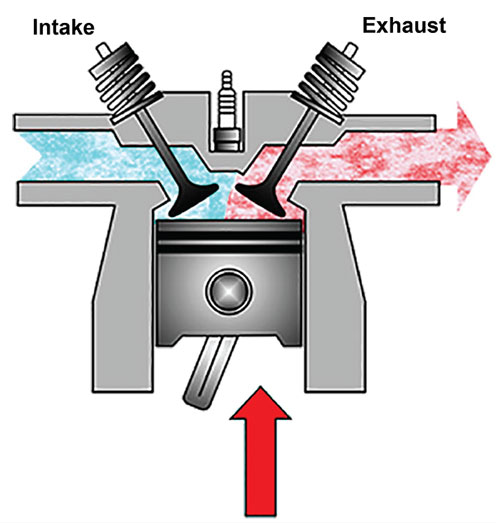

The control solenoid receives a signal from the PCM and meters the flow of engine oil through a series of passages. This moves the sprocket to the advance or retard position. On engines with a fixed camshaft, engineers have to balance between idle quality and performance on one side, and emissions and fuel economy on the other. As a result, none of these goals are achieved completely. Variable valve timing allows the engine to obtain a smooth idle while achieving the rest of the goals. Modern VVT systems combined with technologies like electronic throttle control and direct fuel injection allow smaller engines to produce higher horsepower and torque at a lower RPM.

For increased performance, the exhaust cam is retarded a small amount to promote engine breathing. Higher engine speeds mean shorter valve open times and increased air velocity. The increased velocity pushes more exhaust out of the cylinder. The retarded exhaust valve timing increases Volumetric Efficiency. The exhaust valve is still open when the intake opens. Outgoing exhaust pulse creates a low-pressure zone behind the valve, which increases the pressure differential between the intake port and the combustion chamber. The result is better cylinder filling. Remember, this can’t be done at idle due to low air speeds.

To provide an EGR function, the exhaust cam is fully retarded, which significantly delays the opening of the exhaust valve and adds lots of valve overlap. As a result, the exhaust gas remains trapped in the cylinder. Opening the exhaust valve later retains more exhaust pressure in the cylinder, causing pushback to the intake charge and exhaust gas retention.

On some systems, the intake camshaft is advanced as the throttle opens. The placement opens the intake valve sooner and allows some exhaust gas into the intake stroke, which has an EGR effect. It also closes the intake valve sooner, which increases the compression stroke. On a cold engine, opening the intake valve sooner will also warm the intake charge and assist in reducing startup emissions.

Some newer systems utilize the best of both worlds; they control multiple cams independently of each other. In dual independent systems, the exhaust camshaft is retarded, and the intake valve is advanced independent of each other. Doing so maximizes the EGR effect and further reduces pumping losses for maximum efficiency.

VVT System Failure Causes and Effects

While VVT is a beneficial system, it is not immune to failure. Most failures are caused over time by low engine oil levels, poor oil circulation, or oil and filter change irregularities. Since oil pressure is used to advance or retard many of these systems, it is crucial that the correct specification of oil is used and that oil is changed regularly. Symptoms of issues with a VVT system include a rough idle, engine noise, an unstable idle, stalling, lack of power, and decreased fuel efficiency. Motorists will often be alerted to the issue by the Check Engine light.

In many cases, when a VVT component is being replaced, it is recommended that companion components be replaced at the same time, due to the “in service” time being the same. Similarly, if a timing set is being replaced on an engine with VVT, the VVT components should be replaced. Any time the VVT system is serviced, an oil and filter change is highly recommended.

Choosing the Best Parts for the Job

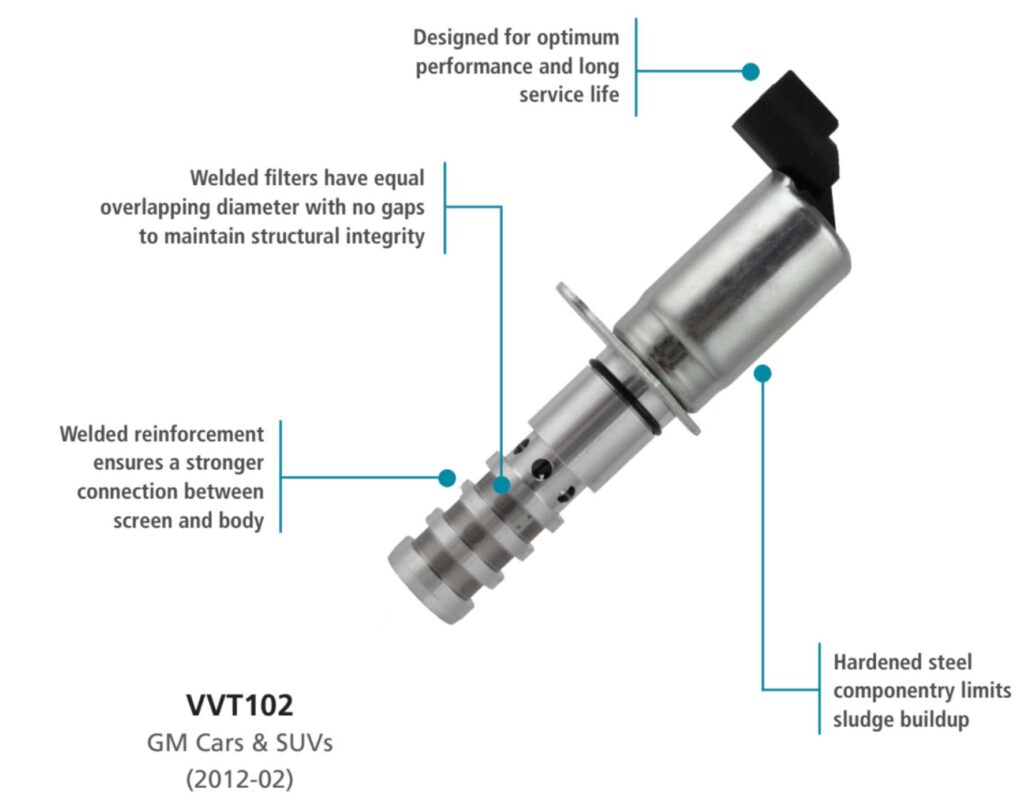

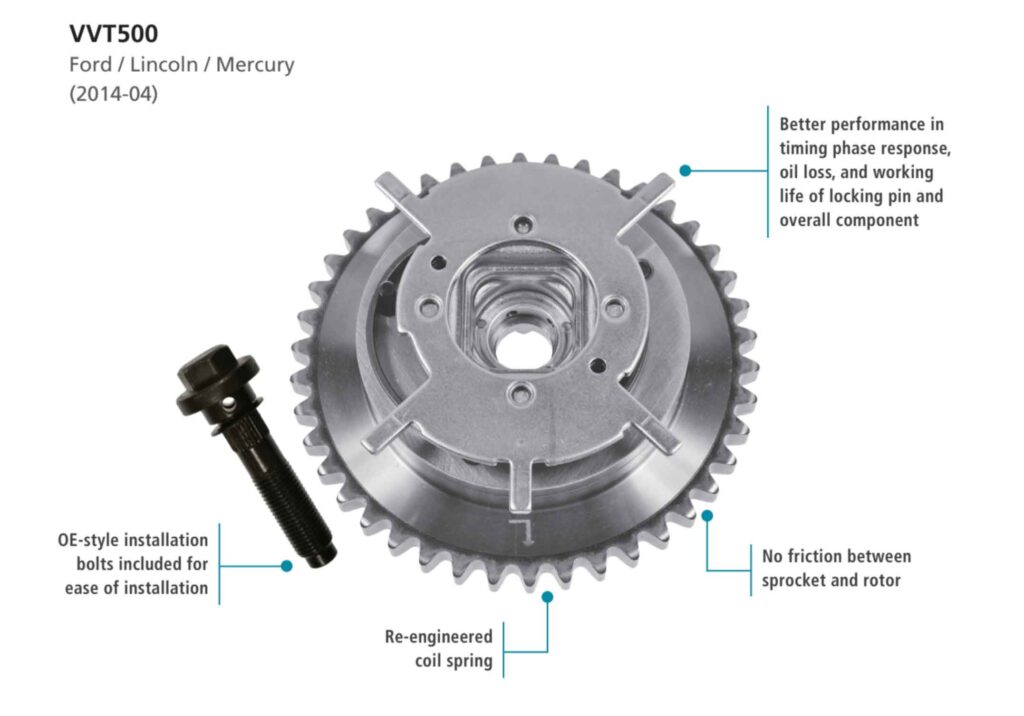

Standard® VVT Solenoids and Sprockets are engine specific, and are engineered to keep complex VVT systems operating as designed. Each Standard® VVT Solenoid

features anodized steel componentry, which limits sludge buildup and protects against sticking. They also feature premium O-rings and gaskets to prevent oil leaks, as well as an OE-match harness connector. Standard® Sprockets are direct-fit OE replacements which meet tight dimensional tolerances to improve internal sealing, minimize oil drain back, and reduce frequency of PCM correction. All Standard® VVT Solenoids and Sprockets undergo a full spectrum of quality testing including thermal shock, thermal cycling, salt spray, vibration, storage tests, and more. The Standard® line also includes several VVT Kits as well as an array of related components including VVT Spool Filters, Chain Tensioner Kits, Position Adjuster Magnets and more.

For more information on replacing these components, search “VVT” on the Standard Brand YouTube channel or visit StandardVVT.com.

Sponsored by Standard®.