MAJOR COMPONENTS & FUNCTIONS

MAJOR COMPONENTS & FUNCTIONS

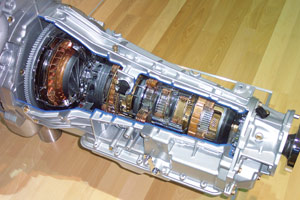

* Transmission — The transmission houses the gears, clutch packs and control hydraulics that transmit and multiply engine torque to the drivetrain. Most automatic transmissions today have four, five or six forward gear ranges. Some vehicles also have “Continuously Variable Transmissions” (CVTs) that have no conventional gears but use a pair of adjustable sheaves with a steel belt to provide an infinite range of gear ratios. The transmission is called a transaxle if it is used in a front-wheel drive (FWD) car, or if it replaces the differential in a rear-wheel drive (RWD) or all-wheel drive (AWD) application.

* Torque converter — A fluid coupling between the engine and transmission that transfers engine torque to the transmission and also provides “torque multiplication” much like a set of reduction gears. Mounted on the flywheel, the torque converter contains a three-piece set of closely spaced blades inside (the turbine, stator and impeller). As the unit rotates, fluid is thrown from one set of blades against the other, much like a propeller churning water. This pushes the blades connected to the transmission input shaft and planetary gears to drive the vehicle down the road. The torque converters in most newer vehicles have a “lockup clutch” that physically couples the engine and transmission in higher gears to eliminate slippage for improved fuel economy. The lockup clutch is engaged hydraulically and controlled by an electronic solenoid valve. The torque converter holds approximately one third of the total fluid required by the transmission. A failure results in slugging acceleration.

* Control devices — This includes the valve body and solenoids which control shifting and engagement/disengagement of internal clutches to change gear ratios, and a vacuum modulator (used on older automatic transmissions to modify the rpm at which the transmission upshifts when the vehicle is accelerating under load). The valve body is located inside the transmission pan and is usually replaced as an assembly if defective, though individual solenoids can be replaced as needed. The modulator on older transmissions is mounted on the side of the transmission, and is connected by a vacuum hose to the intake manifold on the engine.

*Transmission Control Module (TCM) — The electronic module that controls the operation of the automatic transmission. This may be a separate module mounted on or near the transmission, or its functions may be integrated into the Powertrain Control Module (PCM).

* Transmission filter — Usually located inside the transmission pan, the filter protects the transmission against contaminants in the fluid.

* ATF Oil Cooler — A loop of pipe usually located inside the radiator that helps cool the ATF. The cooler can sometimes rust through and allow coolant and ATF to mix. If failed, the radiator must be replaced. For towing or heavy-duty use, recommend the installation of an aftermarket external ATF cooler.

RELATED ITEMS

* Automatic Transmission Fluid (ATF) — Lubricates the transmission, and carries hydraulic pressure to shift gears and transfer engine torque inside the torque converter. ATF is a lightweight mineral oil that contains special additives and friction modifiers required for use in an automatic transmission. It is dyed red to distinguish it from motor oil. Very important: Different transmissions require different types of ATF. Chrysler, Ford, General Motors and most import vehicle manufacturers all have their own ATF specifications. Universal ATF can meet many of these specifications, but many not be compatible with some applications. Follow the ATF recommendations in the vehicle owner’s manual or printed on the transmission dipstick.

ATF can oxidize (burn) if it overheats. This can lead to transmission failure. Changing the fluid periodically for preventive maintenance is recommended, but some owner’s manuals do not have a scheduled replacement interval for ATF. The fluid level should always be maintained between the “full” and “add” marks (which is usually checked when the fluid is warm with the engine idling in Park).

* Gaskets & seals — Replacement pan gasket will be needed when changing the fluid and filter, or to fix a fluid leak. Tailshaft and input shaft seals may also have to be replaced to fix leaks.

* Engine/Transmission mounts — These support the transmission and may have to be replaced if loose, collapsed or broken.

INSTALLING AUTOMATIC TRANSMISSION/TRANSAXLE PARTS

Most internal components are not replaced unless the transaxle is being overhauled. This requires the skills of a transmission specialists as well as special tools.

Replacing the torque converter requires separating the transmission from the engine. On most RWD vehicles, the engine is left in place and the transmission is lowered under the vehicle. On FWD cars and minivans, the transaxle is often mounted on a subframe or cradle that must be lowered to remove the transaxle. This requires supporting the engine from above.