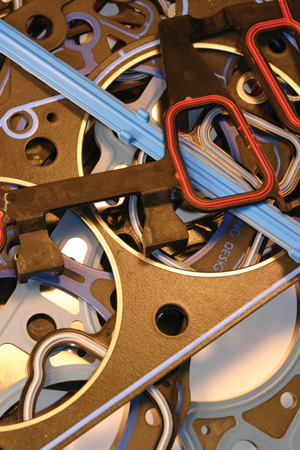

Head gaskets seal the cylinder head to the engine block. The gasket often has a solid or perforated steel core that is faced on one or both sides with a nonasbestos gasket material or graphite. The gasket may also have an

anti-friction or silicon non-stick coating, and/or raised rubber sealing beads printed around coolant passageways and other critical areas to improve sealing. Combustion armor around the cylinders protects the gasket from burn-through. Many late model engines have “Multi-Layer Steel” (MLS) head gaskets with three to five layers of steel. MLS gaskets are very durable but also require a very smooth surface finish on the cylinder head and block.

Head gaskets are not reusable in most cases, so your customer will need a new head gasket if the cylinder head has been removed from the block. Composition head gaskets take a set once they have been installed and torqued down, and MLS gaskets can experience metal fatigue and corrosion over time.

Head gaskets are not reusable in most cases, so your customer will need a new head gasket if the cylinder head has been removed from the block. Composition head gaskets take a set once they have been installed and torqued down, and MLS gaskets can experience metal fatigue and corrosion over time.

MLS gaskets are available as an upgrade for many engines that were not originally equipped with these gaskets. Gaskets that are thicker than stock gaskets are also available to compensate for cylinder head resurfacing.

Most common causes of head gasket failure are engine overheating and detonation. Severe overheating can often warp the cylinder head, so it is important to check the flatness of the head when a head gasket is replaced. If flatness is not within specifications, the head should be resurfaced to prevent a repeat gasket failure. Also, the underlying cause of the overheating needs to be found and repaired so the engine does not overheat again.

Most head gaskets are installed dry (no sealer), as sealer may harm the coating on the gasket. The cylinder head bolts must be tightened with a torque wrench and/or angle gauge to the OEM specifications following a certain sequence. This must be done to evenly load the gasket, otherwise it may not seal properly and leak.

Many late model engines use “torque-to-yield” (TTY) head bolts that are designed to stretch slightly when they are installed. TTY head bolts should not be reused because of the risk of breakage, so a customer replacing a head gasket on one of these engines will also need a new set of head bolts.

Valve cover and oil pan gaskets seal the valve covers and oil pan to the engine. Most of these gaskets on late model engines are molded silicon rubber, but on older engines cork/rubber gaskets are common. Molded silicon rubber gaskets are long-lasting, but swell when exposed to oil, making them difficult to reinstall if removed. Replacing them with new gaskets is recommended for easier installation. Cork/rubber gaskets tend to dry out over time, become brittle and crack. They also take a permanent compression set once they have been tightened down and should not be reused. Molded silicon rubber gaskets are installed dry (no sealer) but cork/rubber gaskets usually require a sealer. Some cork-rubber gaskets have a metal carrier to reinforce the gasket and make installation easier. The bolt holes may also have grommets to limit the compression on the gasket when the bolts are tightened down.

Timing cover gaskets seal the front timing cover to the engine. These gaskets may be paper, cork or molded rubber. Replacement is required when changing timing gears or chain, or a crankshaftdriven oil pump.

Intake manifold gaskets seal the intake manifold to the cylinder heads and engine block. These gaskets may be a fiber or nonasbestos material, with or without steel reinforcement. On many late model engines, composite intake manifold gaskets are used. These may have a plastic or steel carrier with silicone rubber sealing beads around the intake and coolant ports. Some plastic intake manifold gaskets (notably various GM V6 applications) have a poor record for early failure. Coolant leaks are the main problem on the GM applications. Some aftermarket intake manifold gaskets have an improved design that provides better sealing and long-term durability. Intake manifold gaskets should be replaced if the intake manifold is removed.

Exhaust manifold gaskets seal the exhaust manifolds to the cylinder head exhaust ports. These gaskets are usually graphite, MLS or a high-temperature steel-reinforced nonasbestos material. Scrubbing action created by high exhaust temperatures can lead to exhaust leaks. These gaskets should be replaced if the manifolds are removed or replaced. New exhaust manifold bolts are also recommended as the original bolts are often badly corroded from exposure to high heat. Anti-seize compound should also be applied to the threads when the bolts are installed.

Valve guides are installed on top of the valve stems to control lubrication of the valve stems and guides. Worn valve guide seals is a common cause of high oil consumption. On many engines, the seals can be replaced without having to remove the cylinder head from the engine.

Crankshafts have seals on both ends to prevent oil from leaking out of the crankcase. Leaks require replacement. If the seal surface on the crankshaft is worn, a thin steel repair sleeve can be slipped over the end of the crank to restore the sealing surface.

Camshafts usually have a front oil seal, and may have a steel or rubber plug at the back end to prevent oil loss. New seals and plugs should be installed if the camshaft is being replaced.