● SPARK PLUGS — Provide a source of ignition in each cylinder of a gasoline-powered engine. High voltage from an ignition coil passes down through the spark plug’s conductive core and jumps across an electrode gap at the end of the plug to create a spark. This ignites the air/fuel mixture in the combustion chamber and produces power.

The center electrode in a spark plug is surrounded by an insulating ceramic shell. The “heat range” (operating temperature) of the spark plug depends on the length and shape of the ceramic insulator. The spark plug has to run hot enough so fuel deposits don’t build up on the tip, foul the electrode and cause it to misfire. But it also has to conduct enough heat away from the tip so the tip doesn’t get too hot when the engine is under load and cause pre-ignition.

The center electrode in a spark plug is surrounded by an insulating ceramic shell. The “heat range” (operating temperature) of the spark plug depends on the length and shape of the ceramic insulator. The spark plug has to run hot enough so fuel deposits don’t build up on the tip, foul the electrode and cause it to misfire. But it also has to conduct enough heat away from the tip so the tip doesn’t get too hot when the engine is under load and cause pre-ignition.

Spark plugs are designed for specific engine applications. The diameter, length and pitch of the threads that screw into the cylinder head must match the engine along with the heat range. How far the tip of the spark plug extends into the combustion chamber (called “reach”) also must be correct for the application otherwise the tip of the plug may hit the piston or valves. Always follow the spark plug listings in your plug supplier’s catalog or data base.

The distance across the electrode gap at the end of the spark plug must be within specifications for the engine application. If the gap is too narrow, the spark may not be long enough to ignite the fuel mixture reliably resulting in ignition misfire. If the gap is too wide, there may not be enough available voltage to create a spark also causing ignition misfire. Most spark plugs are pre-gapped at the factory, but the gap should always be checked and readjusted, if necessary, when new spark plugs are installed. If your customer does not have a spark plug gapping tool, recommend one.

Over time, the electrodes erode and wear as the miles accumulate. This increases the gap and the voltage required to fire the spark plug. Most conventional spark plugs have a recommended replacement interval of 30,000 to 45,000 miles. To extend plug life to 100,000 miles, platinum or iridium electrodes are used in long-life spark plugs. Iridium is the newer alternative to platinum, with several spark plug manufacturers introducing new iridium spark plugs in the past year. Some long-life spark plugs (such as Bosch +4 and +2) have additional ground electrodes to reduce electrode wear even more.

To improve ignition performance, some manufacturers offer spark plugs with special electrode configurations that expose more spark to the air/fuel mixture. Performance plugs reduce misfires and improve fuel economy and power, and are a good upgrade for customers who need the ultimate in ignition performance.

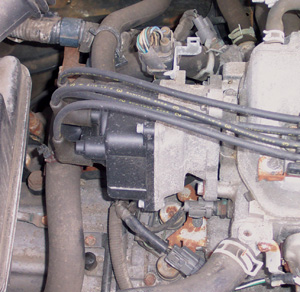

● IGNITION COILS — Provide the high-voltage current for the spark plugs. The coil is a transformer that steps up battery voltage (12 volts) to tens of thousands of volts in order to create a strong spark. Inside the coil are two sets of copper wire windings, one inside the other. The primary windings are made up of several hundred loops of heavy wire around the iron core of the coil. The secondary windings consist of several thousand turns of very fine wire inside the primary windings.

When battery voltage flows through the primary windings, the coil becomes a very strong electromagnet.

When the ignition module shuts off the primary current, the magnetic field collapses and induces a high-voltage surge in the secondary windings. The high voltage is then routed from the coil to the spark plugs to create a spark.

Most late model engines have some type of distributorless ignition system (DIS). This includes “waste spark” DIS systems with coil packs and plug wires, Coil-On-Plug (COP) ignitions (with no spark plug wires), and Coil-Near-Plug (CNP) ignition systems with individual coils for each cylinder and short spark plug wires.

Older vehicles with distributors typically have a single coil. The coil may be an oil-filled “can” type mounted near the distributor, an epoxy round or square coil, or a compact coil that mounts inside the top of the distributor cap (GM HEI distributors). Some older import ignitions have two coils.

Cracks in the coil housing or carbon tracks around the high voltage output terminal can cause ignition misfire. Internal shorts or opens in the coil windings can reduce its voltage output, causing hard starting and ignition misfire. If a coil fails, an engine with a distributor and single coil will not run. If an individual coil on a DIS or COP ignition system fails, it will cause a misfire only in the cylinder(s) supplied by that coil. On some DIS ignitions, the entire coil pack must be replaced if only a single coil has failed. On others, the coils can be replaced individually.

● IGNITION CABLES — Carry voltage from the coil to the spark plugs. Used with distributor ignition systems, DIS multiple coil systems, and Coil-Near-Plug (CNP) ignition systems. Ignition cables come in various types (suppression and solid core), use different types of insulating and jacketing materials (silicone, EPDM, etc.) and come in different lengths and diameters (7 and 8 mm). Replacement cables must be the same size and length as the original. Cables may be replaced individually or in complete sets (cables should be changed one at a time to avoid mixing up the firing order). Recommend a complete set if more than one of the original cables is bad. Replacement is needed if internal resistance in a cable exceeds specifications, the cable is damaged (cracked or burned insulation, or visible arcing or misfiring when the engine is running), or the plug boots or terminals fit poorly or are loose.

● DISTRIBUTOR CAP AND ROTOR — Used on older distributor ignition systems to route high voltage from the coil to each individual spark plug in a specific firing sequence. The rotor is located inside the cap, and turns at the same speed as the camshaft (half engine speed). High voltage current from the coil enters the center terminal of the cap, goes to the rotor and then jumps from the tip of the rotor to the nearest spark plug terminal. Over time, the tip of the rotor and the terminals inside the distributor cap can become worn and covered with deposits that interfere with the spark. The cap and rotor should be inspected when the spark plugs are changed, and replaced as needed. A cracked cap or rotor may cause ignition misfire or prevent the engine from running.

● DISTRIBUTOR — Used on older engines to direct high voltage to the individual spark plugs in a specific firing order. The distributor is mounted on the engine and driven by the camshaft. The distributor contains an electronic pickup (magnetic, Hall effect or optical) for generating a trigger signal to fire the ignition coil. An ignition module also may be mounted inside or on the distributor to control coil operation and spark timing (unless these functions are controlled by the PCM). The distributor may have to be replaced if the shaft bushings or cam gear are worn.

● IGNITION MODULE — Used in electronic ignitions to switch the ignition coil on and off. Contains a switching transistor and circuitry that picks up ignition timing pulses from the distributor. A module failure will prevent the engine from running (no spark).

On distributorless ignitions, the module is usually part of the coil pack and receives its ignition timing pulses from a crankshaft position sensor. Or, the PCM may control the ignition system.

● CRANKSHAFT POSITION (CKP) SENSOR — Used with distributorless and COP ignition systems to create a timing signal for the ignition system. The sensor typically reads notches in the crankshaft balancer, flywheel or crankshaft. Two types are used: magnetic and Hall effect. Magnetic sensors produce an alternating current (AC) signal that changes in frequency and amplitude with rpm. Hall effect switches produce an on-off digital signal. Loss of the CKP sensor signal will prevent the engine from starting (no spark).

Ignition System

Manual Transmission/Transaxle Parts

Emission Controls

Driveline Components