NTN, the parent company of Bower Bearings, announced the addition of pre-adjusted commercial-vehicle wheel-end kits to its heavy-duty product line.

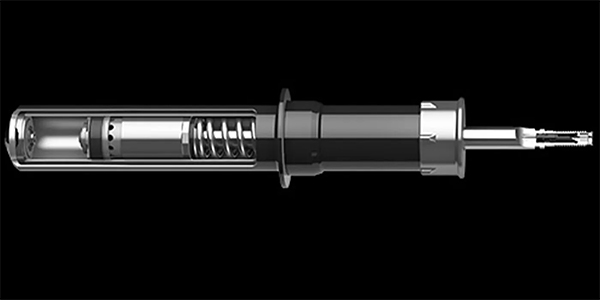

Combining Bower’s precision-engineered tapered roller bearing sets with a precisely machined cone spacer, the wheel-end kits provide solutions for the heavy-duty truck industry’s most popular wheel-end applications.

The kits use a precision-engineered, high-strength alloy steel spacer to achieve the proper amount of endplay on the two included sets of precision tapered roller bearings. The kit allows a technician to use the OE installation procedure for easily repeatable, consistent and accurate installation without the need for time-consuming, manual adjustment of bearing endplay, according to the company.

“We have listened to the demand from our heavy-duty customers, and we are proud to provide them a solution to a common maintenance issue faced by heavy-duty fleets,” said Matt Gorski, manager of product management for NTN’s automotive aftermarket. “Eliminating the need for manual adjustment of wheel-bearing endplay reduces installation time and margin for error, resulting in maximized uptime.”

Bower pre-adjusted commercial-vehicle wheel-end kits are now available to Bower’s North American distributors in popular applications for steer, drive and trailer axles. The kits will make their public debut in Bower’s booth (No. 1617) at Heavy Duty Aftermarket Week 2020, which takes place Jan. 27-30 in Grapevine, Texas.