Ignition coils come in a wide range of shapes, sizes and applications. Distributor-type, and distributorless ignition systems all rely on one or more ignition coils to transform battery voltage into the higher voltage required to jump the spark plug gap and efficiently ignite the air-fuel mixture. The distinct differences between coil designs make identification of optional coils relatively simple for both the parts specialist and the technician. While newer coil designs are often unique and very application-specific, the so-called “universal” coil still creates a good deal of confusion at the parts counter.

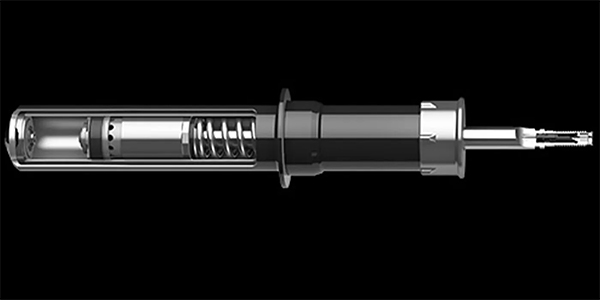

The canister-type coil is commonly found in breaker-point ignition systems, as well as some early breakerless systems. In addition, this coil design is popular among performance ignition manufacturers. Far from obsolete technology, these coils are still a stocking item at many parts stores, and come in two distinct types. Unfortunately, their external appearance is so similar that only the manufacturer’s labelling or a resistance (ohms) test can differentiate between the two types. Simply selecting any “universal” canister-type coil found in the catalog or on the shelf is a common mistake, often leading to ignition performance issues, unhappy customers and “defective” returns.

The canister-type coil is commonly found in breaker-point ignition systems, as well as some early breakerless systems. In addition, this coil design is popular among performance ignition manufacturers. Far from obsolete technology, these coils are still a stocking item at many parts stores, and come in two distinct types. Unfortunately, their external appearance is so similar that only the manufacturer’s labelling or a resistance (ohms) test can differentiate between the two types. Simply selecting any “universal” canister-type coil found in the catalog or on the shelf is a common mistake, often leading to ignition performance issues, unhappy customers and “defective” returns.

For 12V universal coils, there are two categories: those coils with an internal resistor, and those for use with an external resistor. This seems to be the most common source of confusion, as many customers (and some counterpeople) don’t understand the differences between the two systems. Coils with an internal resistor have a resistance value of approximately 3 ohms across the primary circuit (between the + and – terminals), while coils designed for use with an external resistor have roughly half that resistance (1.5 ohms). An external ballast resistor (like those commonly cataloged for classic Mopars) or a resistance wire contributes another 1.5 ohms to the circuit. The net effect is the same, with a 12V supply and 3 ohms of total resistance, the result is 4 amps of current flowing through the circuit. (12 volts / 3 ohms = 4 amps)

Interchanging these two types of ignition coils can have one of two very different effects on the ignition system. The use of an “internal resistor” coil in an ignition system equipped with an external resistor will cause excessive resistance in the system, leading to weak coil and spark output. In a system requiring an “internal resistor” type coil, the use of the external resistor style coil can lead to heat failure of the ignition coil. In vehicles equipped with breaker points, this can also cause premature wear/burning of the points. Using the same formula as before, with a 12V supply and only 1.5 ohms of resistance, the resulting current flow is doubled to 8 amps.

Occasionally, a customer may request a 6V coil for their classic vehicle, or possibly a vintage tractor. While the primary resistance of the correct 6V coil and the 12V external-resistor coil are similar (and I have heard of a few old-timers using them interchangeably on vintage tractors), using the 12V coil with an internal resistor can drop the current below the threshold required to fire the plugs reliably, especially at higher RPMs. Attempting to use a 6V coil in a 12V system (or a 12V coil in a 24V system) will lead to rapid coil failure, so choosing the correct coil for the application is critical. For customers considering the popular 6V to 12V conversion, be sure to recommend the appropriate 12V ignition coil along with the new battery, alternator and accessory electrical components.