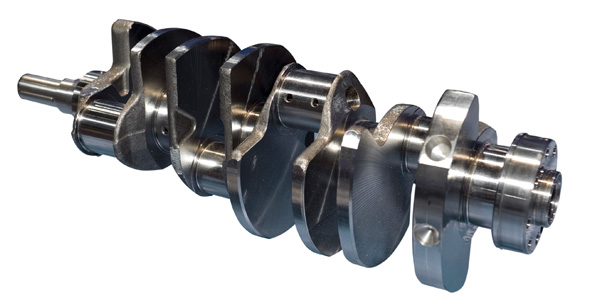

The “bottom end” of an engine assembly consists of the block and crankshaft, as well as the pistons and connecting rods. This also is commonly referred to as a “short block,” and the crankshaft is the most significant individual replacement part contained within the short block. Fortunately for our customers, this costly chunk of iron or steel isn’t a regular replacement item. Unfortunately for many counter professionals, this also means they may not be all that familiar with the basics of crankshaft materials, design and selection.

There are three basic categories when it comes to crankshafts: cast, forged and billet. The majority of OEM crankshafts are made of cast iron or cast steel. Molten metal is poured into a sand casting to create the basic shape of the crank, then this raw casting is machined to its final tolerances. This is a fast and inexpensive way to create mass-produced crankshafts that are up to the challenges faced by everyday production engines. Cast cranks, depending on their design and material, are capable of handling up to 300 hp or even 500 hp, well above the limits of most “normal” production vehicles.

Manufacturing a forged crankshaft is a considerably more involved process, but yields a stronger crankshaft potentially capable of handling up to 1,500 hp. Forging begins with a chunk of steel alloy, which is hammered into shape using heavy presses and dies. After being beaten into its general shape, the crank forging then requires a great deal of machining before it is a finished product. Forged crankshafts were used in many heavy-duty and performance-oriented production engines during the 70s and 80s, and many old-school customers still equate “forged” with “better.”

Some engines were assembled with either cast or forged cranks during their production runs, so identifying the type of crank is sometimes important for selecting components. In the absence of actual part numbers stamped or cast into the crank, one simple way to tell is to compare the “parting lines” imprinted on the non-machined portions of the crank. Cast cranks have a sharp or very narrow ridge where the two halves of the mold were separated. Forged cranks have a wider (1/2-inch or more) irregularly shaped parting line.

The third type of crankshaft is the “billet” crank. Like a forged crank, this unit begins life as a solid chunk of forged steel, but rather than pounding it into submission, the billet is entirely CNC-machined to create a finished piece. Billet cranks are very strong, and the CNC machining allows for designs that cannot be created by forging, but they also are very expensive. If your store handles performance parts, you may have a vendor who offers billet cranks.

Billet cranks are great choices for NASCAR and NHRA teams, but your average customer doesn’t require this kind of bottom-end durability — or the expense that goes along with it. Cast crankshaft kits will be probably be sufficient for 99 percent of your customer base, with a few requests for forged cranks here and there.