http://gty.im/187367951

By Charlie Covert

UPS

We’re living in the age of disruption – and that is increasingly true for the automotive aftermarket. Technology is empowering customers to dictate more of their purchasing experience, and consumers are more educated than ever before about each and every step in a given supply chain.

Like in other industries, automotive consumers expect to get what they want, when they want it and how they want it delivered. The ways of the past are becoming obsolete more quickly than many of us could have predicted.

Why should this matter to manufacturers, distributors, wholesalers and retailers?

Serving this new breed of consumer requires a complex network of business-to-business and business-to-consumer collaboration, especially through e-commerce, which includes highly efficient inventory management and replenishment, product delivery and returns.

E-commerce is effectively providing a higher level of visibility and flexibility across the supply chain, and businesses most adept at meeting these new demands have realized that this greater level of control offers them a competitive advantage.

With quicker turnaround times, brick and mortar stores have evolved into mini fulfillment centers, driving the omni-channel supply chain approach that has become a requirement rather than a choice. If your online properties aren’t equipped for smartphones and tablets, buyers are probably getting a better experience from your competitors.

This underscores the importance of optimizing your supply chain, an ever-evolving task that separates the business of the future from those unable to move beyond business as usual.

What’s driving the disruption?

What started as a retail phenomenon in which consumers demanded a seamless online and retail experience has spread to the automotive industry, among other sectors. This expansion of an omni-channel strategy means speed to market has gotten even more important for your business.

What started as a retail phenomenon in which consumers demanded a seamless online and retail experience has spread to the automotive industry, among other sectors. This expansion of an omni-channel strategy means speed to market has gotten even more important for your business.

With the prevalence of e-commerce, business-to-business customers are increasingly buying straight from manufacturers. There has also been a high level of consolidation among automotive and industrial parts distributors.

Sales channels are becoming integrated. Customers no longer separate your physical building from your website or social media pages. They expect to interact with you seamlessly, irrespective of the medium – sometimes though multiple platforms at once. In fact, individual customers are deciding how and when they interact with you. They control this process, not you.

This is a disruptive technological experience.

Put more bluntly: Catalogs and sales representative relationships aren’t enough anymore. Distributors must showcase an unparalleled level of value to remain relevant.

You’ve also likely heard about 3D printing being used to make seldom-sourced or hard-to-find parts. Not far from UPS’s Worldport airline hub, CloudDDM, a new business, utilizes industrial grade, high-tech 3D printers, running them 24 hours a day. They make parts for companies in a number of industries, including at least one automotive business. Applications for additive manufacturing are expanding rapidly and becoming more integrated into supply chain strategy.

As new technologies infuse the marketplace, real-time visibility across every part of the supply chain will be expected – regardless of the size of your company. At the same time, business and supply chain modeling is becoming more accessible. Improved data analytics is resulting in more robust business model simulation, an invaluable tool for manufacturers and distributors in a rapidly changing world.

B2B is leading B2C

Traditionally, business-to-business transactions were treated differently than those in the business-to-consumer realm. B2C drove B2B practices – that’s no longer the case. We all bring our experiences as consumers to work, transforming our expectations for how businesses can improve.

Companies are so rich in data and operate systems so complex that e-commerce and supply chain management have become central selling points in attracting and retaining business customers, as well as end consumers. This approach is permeating industries from high tech and healthcare to industrial manufacturing and automotive.

An opening for small business?

To obtain a true omni-channel experience, manufacturing, warehousing, distribution, wholesale and retail operations must be integrated. While tempting for small businesses to dismiss such a strategy as unique to bigger companies, they risk passing on a competitive advantage.

With distributors under growing pressure to exhibit value, smaller businesses are in a terrific position to leverage online technologies in ways that level the playing field with larger companies. It’s just a matter of finding the right formula for your specific business.

There is no one, “right” way to invest in your supply chain. It’s all about strategy. For example, do you want every part available within 30 minutes or two days?

If you solely look at the flow of parts from supplier through distribution center to the customer, you’re just reviewing one side of the equation. Don’t forget to analyze the process from the customer’s perspective.

- How much are you – and your customers – paying for shipping?

- How long does it take for parts to arrive after they’ve been ordered?

- Can you make adjustments to receive parts in the same amount of time for less money or more quickly for the same cost?

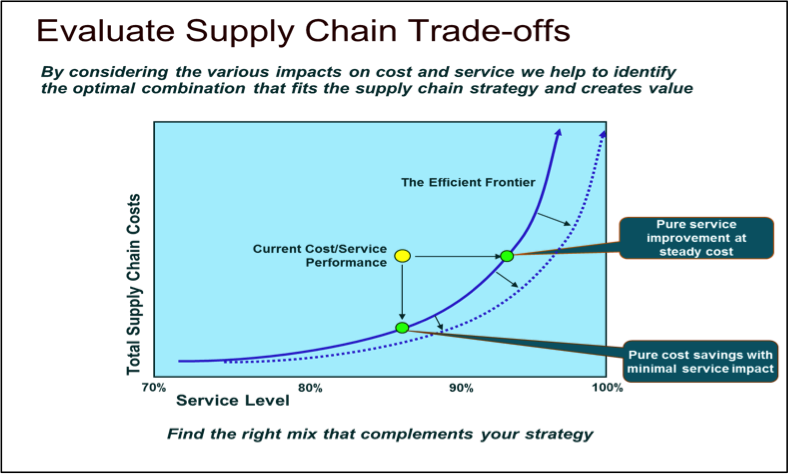

Effectively managing the supply chain involves balancing tradeoffs, particularly between cost and service.

As outlined in this graph, the solid line represents the “Efficient Frontier,” which is the optimal balance for any particular cost or service level within a defined business model. Any operation above or to the left of this line can be further optimized.

Optimizing your supply chain

Once you have identified your cost efficiency, then you can pinpoint potential improvements. This should be an ongoing practice, regularly refined as your business grows, new technologies enter the marketplace and customer behavior evolves.

If you haven’t done an audit on your customer engagement and supply chain methods in the last 12 to 18 months, you’re due.

Never underestimate the power of asking, “What if?” This allows you to step back and assess how the market is changing and identify new opportunities.

At UPS, we call this “constructive dissatisfaction.” Whatever you want to call it, be candid with yourself, pursue those opportunities – measure the results – and push the boundaries of what is possible.

Charlie Covert is Vice President, Customer Solutions, at UPS where he is responsible for supply chain design, sustainability, and consulting for the automotive, aerospace, government, professional services and industrial manufacturing sectors.