As a parts pro, you have a lot of influence on your customers’ purchasing decisions. Often, they’ll ask for your advice, or you may notice they forgot something that could be needed for the job to be done correctly – which is the case with replacing brake hardware. Techs tend to forget about the hardware unless it’s included with the brake pads. And just as often, the sale is missed because you didn’t ask about the hardware.

Every time the brake pads are changed, new hardware should be installed. Brake-hardware styles vary, depending on the type and design of the system. Drum brakes have more hardware than disc brakes, for instance. Brake-hardware manufacturers typically sell all of the required parts and pieces in a hardware kit for each axle (that’s two sides).

On disc-brake systems, the caliper is located on the rotor by two slide pins that allow it to center itself as the pads are pressed against the disc. The slide pins are prone to rust and corrosion and should be replaced if they’re not in good shape. Pitting can occur, which might make the surface rougher and not allow the pin to slide as easily as a new pin.

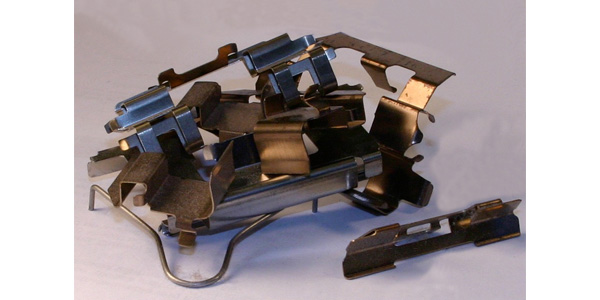

The clips and other parts included with many hardware kits must be replaced regularly, as they can wear or lose the spring-force over time. Rust and corrosion also are common on these components. Caution your customers to be on the lookout for missing clips, bent slide pins and broken return springs, and to do a thorough visual inspection any time the pads or shoes are replaced. The primary objective is to make sure any moving parts in the system can move as smoothly as intended.

Pad slides, which often are called “fit kits,” are incorporated on many modern disc-brake systems. The slide consists of a thin piece of metal that sits on the caliper bracket to give the brake pad a smooth surface to slide on and keeps them from rattling and making noise. A return spring or pad spreader also may be included, which holds the brake pads away from the rotor surface when the brakes aren’t being applied.

Vehicles with rear disc brakes frequently utilize an auxiliary drum brake for the emergency brakes. The drum brake is built into the back of the rotor and is much smaller than a regular drum. The auxiliary drum brake typically uses the same type of hardware as a conventional drum-brake system.

The parking-brake system also should be inspected, as it may not be used as often, if at all. The cable can stick or corrode, making the parking brake inoperable.

As a final note, after you’ve added the hardware kit, make sure to inquire about high-temperature brake lubricant. Most shops buy it in large quantities, but DIYers usually don’t stock up on the stuff. Using bearing grease or other types of lubricant may contaminate the pads, so be sure to recommend the right product.