Technician: I need a blower motor resistor for this 2016 Ford F150 I’m working on.

Counterperson: Would you like to replace the electrical connector with that?

If this isn’t a question you’re currently asking your customers, it certainly is one that you should! As blower motors begin to weaken or are contaminated with debris, they draw excessive electrical current, eventually burning out the resistor, and in many cases causing the electrical connector to melt. If the source of excessive draw or the electrical connector isn’t replaced, the likelihood of a repeat failure is high.

What Do Blower Motor Resistors Do?

Blower Motor Resistors control the electrical current flowing from the fan switch to the blower motor, which allows the motorist to set the fan at different speeds. The fan speed can be changed mechanically, using a rotating lever that selects a different electrical path of resistance in the blower resistor, or automatically by an HVAC control module.

What Are The Common Causes Of Failure?

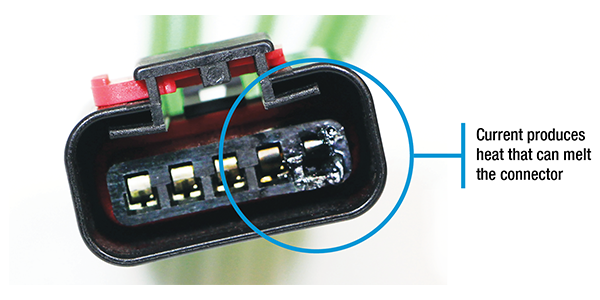

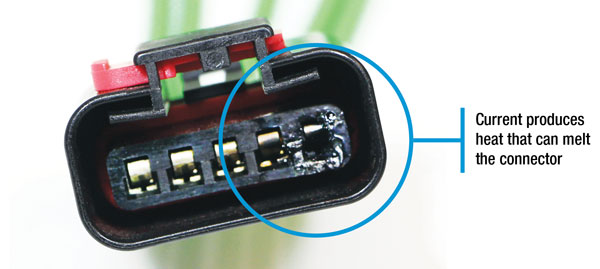

Due to technological advancements on today’s automotive heating and cooling systems, blower motor resistors have high amounts of current running through their connectors, producing heat that can melt the connector and resistor. Worn OE blower motors can create a demand that also damages the resistor or module as the excess current melts the wiring and plastic shroud, damaging the interface pins on the controller’s circuit board.

Tech Tip: Burnt OE connector

For diagnostics, technicians should use an inductive amp clamp to check that the blower motor current draw is less than 80% of the fuse rating on high. If the current is too high, replace the blower motor or the new resistor will fail too. The mating connector also should be inspected for signs of damage caused by excess heat.

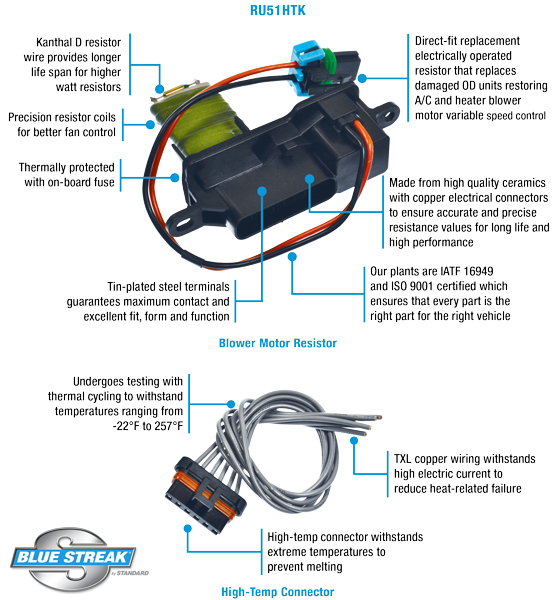

The Blue Streak® solution: Blower Motor Resistor Kits featuring problem-solving high-temp connectors

Blue Streak® by Standard® premium Blower Motor Resistor Kits are a high-quality solution for melted connectors and blower motor resistors. Blue Streak® engineers improved on the OE design to create a connector that will withstand the excessive heat and reduce future failure.

Blue Streak® connectors undergo thermal cycling testing to withstand extreme temperatures to prevent melting. Blue Streak® blower motor resistors are direct-fit replacements and engineered to withstand the high levels of current that can melt the resistor or connector.

Next time a customer calls and asks for a blower motor resistor, help them avoid a repeat failure and recommend that they purchase a Blue Streak® Blower Motor Resistor Kit to do the job right.

For more information, visit BlueStreakBMRK.com or check out our Blower Motor Resistor playlist on YouTube.

This article was sponsored by Blue Streak® by Standard®