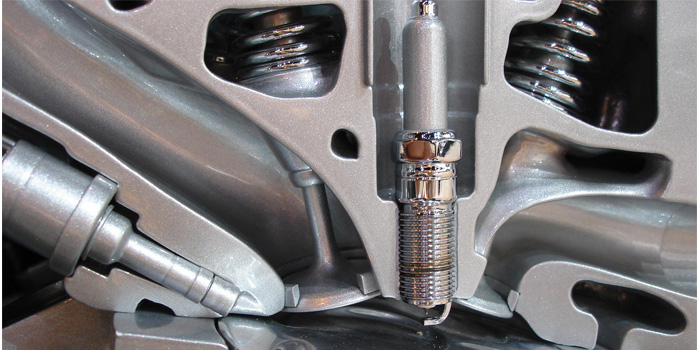

Except for diesels, all internal combustion engines have spark plugs to ignite the air/fuel mixture – at least one spark plug per cylinder, and two plugs per cylinder in some engines such as late-model Chrysler Hemi V8s, as well as certain Honda, Mercedes, Nissan and Toyota engines. Back in the 1980s and 1990s, Ford’s 2.3L four-cylinder engine had two plugs per cylinder. Twin plugs are also found in many motorcycle engines, as well as aircraft piston engines.

Except for diesels, all internal combustion engines have spark plugs to ignite the air/fuel mixture – at least one spark plug per cylinder, and two plugs per cylinder in some engines such as late-model Chrysler Hemi V8s, as well as certain Honda, Mercedes, Nissan and Toyota engines. Back in the 1980s and 1990s, Ford’s 2.3L four-cylinder engine had two plugs per cylinder. Twin plugs are also found in many motorcycle engines, as well as aircraft piston engines.

Two spark plugs per cylinder may be used to improve ignition reliability. By placing the spark plugs at either side of the combustion chamber and firing both plugs simultaneously, the flame front has less distance to travel. This produces a faster, cleaner burn with lower emissions. It also reduces misfires in high revving engines. In aircraft applications, each spark plug fires independently via two separate ignition systems. This provides an extra margin of safety should one ignition system fail.

When a single spark plug is mounted in the center of the combustion chamber, the flame front has a further distance to spread when the plug ignites the air/fuel mixture. This may result in a less than complete burn (increased emissions) as well as misfires at high RPMs.

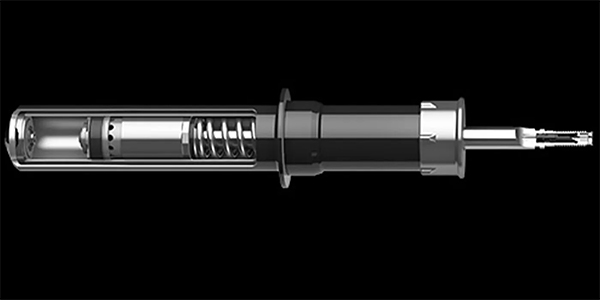

Regardless of how many spark plugs are used per cylinder, plug life remains the same whether the engine has one or two plugs per cylinder. Spark plug life is a function of how many times each plug fires for every mile driven. The more the plug fires, the faster the electrodes wear. As the electrode gap widens, the firing voltage requirements go up, increasing the load on the ignition system. Eventually, this leads to ignition misfires, loss of performance, fuel economy and higher emissions. How quickly the electrodes wear away depends on the materials used in the plugs. With standard copper core spark plugs, the nickel alloy steel center electrode and plain steel ground electrode typically wear out in 40,000 to 60,000 miles of driving. With long-life platinum plugs, the lifespan is usually 100,000 miles. Iridium plugs are even better with many lasting up to 120,000 miles. Long-life plugs with double platinum electrodes (platinum center and ground electrodes) and iridium/platinum plugs (iridium center electrode with platinum tipped ground electrode) are even more durable.

A 100,000-mile spark plug may not go the distance if it has become fouled. Plug fouling occurs when deposits build up on the electrodes causing the plug to misfire. Carbon deposits can foul the plugs if an engine is burning oil. Replacing the spark plugs will temporarily solve the misfire problem, but the new plugs will likely foul before too many miles unless the underlying oil consumption problem is fixed.

Fuel deposits can also foul plugs if the engine spends a lot of time idling or is never driven far enough or fast enough to heat up the plugs and burn off the deposits. Cleaning or replacing the plugs can correct the fouling problem, but only temporarily if the vehicle still spends too much time idling or is seldom driven. Replacing the stock spark plugs with ones that have a slightly warmer heat range can help prevent this type of fouling.

Other parts that a customer might need when changing spark plugs include a plug socket, plug gapping tool, spark plug wire set or a new distributor cap and rotor (for older vehicles). Plugs in engines with aluminum heads should be changed when the engine is cold. Using anti-seize on plug threads is not recommended because it increases the risk of over-tightening the plugs and damaging the threads in the heads, and it may smear and foul the electrodes.