McHENRY, Illinois – Raybestos has increased coverage of its premium-quality Rust Prevention Technology (RPT) rotor and caliper product lines with the recent addition of 67 rotor part numbers and 72 caliper part numbers.

“The timing of new RPT Rust Prevention Technology rotor and caliper part-number introductions couldn’t be better, as large parts of the country are currently dealing with harsh winter-weather conditions and corrosive road treatments,” said Kristin Grons, marketing manager for Brake Parts Inc. “Raybestos RPT coated rotors and plated calipers provide all-weather protection against the elements, including snow, salt and rain, inhibiting corrosion and rust.”

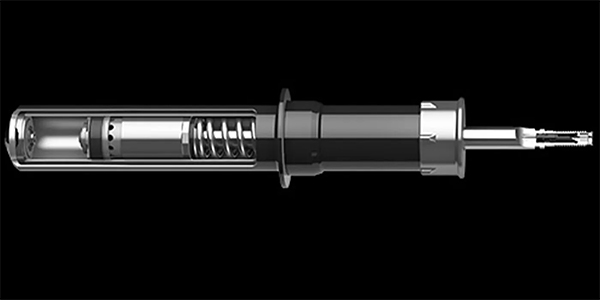

RPT coated rotors use a propriety finishing technology to evenly coat each rotor’s entire surface, including the cooling vanes, according to parent company Brake Parts Inc. The full Grey Fusion 4.0 coating helps resist corrosion and significantly delays rust-induced performance issues, according to the company.

Open-wheel designs on modern vehicles leave brake parts, particularly rotors, more exposed to the elements. If a rotor is uncoated, corrosion and red rust begin to form immediately.

RPT plated brake calipers are engineered to face the toughest weather conditions. A proprietary zinc electroplating process helps prevent rust and provides protection for all kinds of weather, according to Brake Parts Inc.

“The plated brake calipers maintain their high-quality appearance throughout their service life, delivering continued functionality and an extended service life,” the company added.

In total, Raybestos added 372 part numbers during the fourth quarter of 2017, including 151 brake rotors, 41 brake pad sets, 98 brake caliper and brackets, 10 brake calipers, 16 master cylinders, 13 brake hoses, two wheel cylinders, 33 hardware numbers and eight wheel hub assemblies.

For more information on the complete family of Raybestos brake products, including disc pads and shoes, drums and rotors, wheel cylinders, calipers, hoses and hardware, visit the Raybestos website.