Selling shocks and struts simply comes down to knowledge, and sometimes it’s a little tricky because many of our customers confuse the difference between shocks, springs and struts. So, let’s start by clarifying the difference with information you can pass on the next time you get into the conversation across the counter.

The suspension of a vehicle includes every component that supports the weight of the vehicle and travels up and down in response to the road surface, driving conditions or vehicle load. Springs are the components that support that actual weight of the vehicle, but they’re just one part of the suspension. Shock absorbers are the components that dampen the movement of the springs, but again, they too are just one part of the suspension.

In a traditional upper and lower A-arm front suspension (one of the oldest styles), the shocks and springs mount in separate locations, and the springs are either coil or torsion-bar type. Vehicles with this type of suspension – such as older full-frame vehicles and full-size trucks – typically have solid-axle leaf- or coil-spring rear suspension, in which, of course, the springs and shocks also are separate components.

Struts

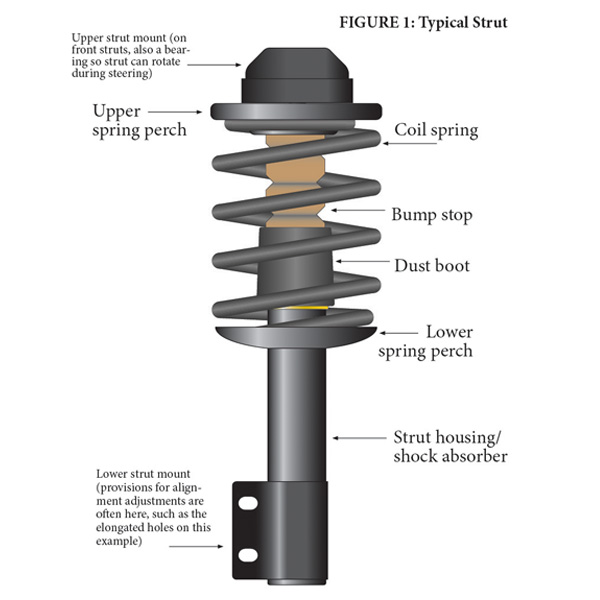

The term “strut” is a shortened reference to the MacPherson strut design of suspension. A strut suspension differs from a “traditional” suspension in the manner that the spring and shock are assembled together as a unit that mounts to the vehicle body on top, and an axle component on the bottom. The top of the assembled unit includes rubber mounting, and in the case of front suspension, a bearing to allow it to rotate in response to steering (Figure 1).

The assembled coil-spring and shock-absorber unit is referred to as the strut, but from a functional standpoint, you can still think of them as a shock, spring and related mounting components – because that’s all they are.

Coil-Overs

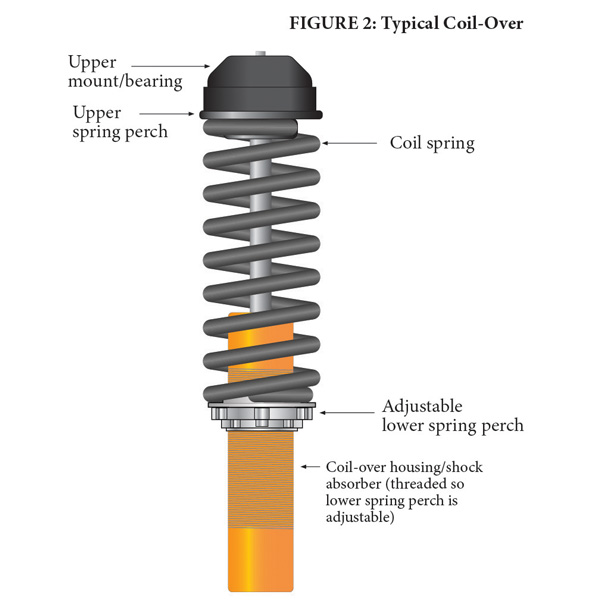

So, what’s a coil-over? It’s a coil spring mounted over a shock absorber (Figure 2). Sound sort of like a strut? Guess what? It’s basically the same thing. The only difference is that coil-overs typically are smaller with adjustable coil-spring perches, which makes them a very versatile choice for performance suspensions, allowing adjustable ride height and use in a variety of suspension designs. But again, don’t let the fancy name throw you: It’s just a spring and a shock.

In addition to these, there are many different types and variations of suspension; definitely a topic for another article, but for the sake of this discussion, regardless of what they are, there are always springs that support the weight of the vehicle and shocks that dampen the movement. Most new cars and small SUVs have strut front suspension. Some have strut rear suspension, but separate coil-spring/shock-absorber rear suspensions are just as common. Full-size trucks and SUVs typically have upper/lower A-arm suspension in front and leaf-spring suspension in the rear.

For many years, suspension springs in general were never a problem for technicians. They rarely broke, and it took a long time before they sagged or weakened, regardless of the style of suspension. Shocks wore out frequently – a common problem – and we’ve all replaced many shocks over the years. If it was a car that had strut suspension front or rear, you removed the strut assembly, compressed the coil spring, removed the top plate and disassembled the strut.

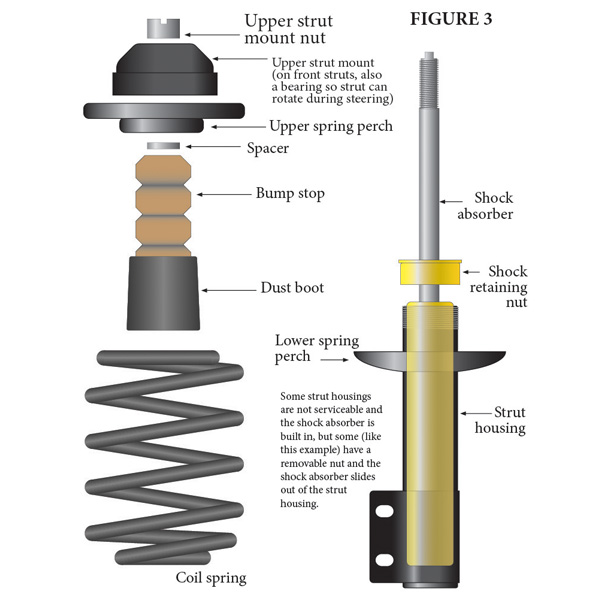

Parts of a strut included the upper plate/bearing, coil spring, bump stop, dust boot, various washers or spacers and the shock-absorber/strut housing itself (Figure 3). Sometimes, the lower spring perch is a separate piece that slides onto the shock/strut housing, and sometimes it’s part of the strut housing. The shock-absorber/strut housing may be one piece (not serviceable), but often, replacing the shock absorber itself was yet another step that included removing a large nut on the top of the strut housing and sliding it out.

The strut housing was reused, a new shock was installed (or if not serviceable, the housing was replaced), then the original spring was reinstalled along with a new upper mount and hardware. I’ve probably done it a thousand times, until … dun, dun dun …the quick strut!

But before we get into that fast fix, let’s drive it home with a final word of wisdom: Shocks are not struts, and struts are not shocks, but a shock is part of a strut. The closest you get is when the strut housing isn’t serviceable, and the shock absorber and strut housing are one piece. On a vehicle that has separate suspension springs and shocks, you can replace one or the other. On a vehicle that has strut suspension, you also can replace one or the other. Think about it like this: Regardless of the type of suspension, the same components are there, and they do the same things – they just differ in the way they are put together.

Every time a shock absorber is collapsed or expanded, oil is forced between different chambers, through a small orifice inside. The effort that it takes to force the oil through is what dampens the suspension movement, and you can feel the resistance when you attempt to move the shock rod by hand.

What makes them good or bad? If there’s no resistance in the movement of the shock rod, the shock is bad. It can’t dampen the movement of the suspension, and when you hit a bump, the car will bounce like a pogo stick. On the freeways around here, I see it at least once a day.

Traditional shock absorbers commonly experience aeration, meaning air bubbles mix in the oil. This causes a similar effect as air in brake fluid, and the performance of the shock absorber diminishes. The solution? A gas-charged shock. The pressure keeps the air bubbles from forming, creating consistent performance. Traditional shocks tend to provide a slightly smoother ride; the type of ride we are used to in a big-old car, whereas gas-charged shocks will stiffen up the ride feel slightly but offer better handling performance.

Service Life of Shocks

How long a shock absorber lasts depends on many factors such as age and mileage, but one of the biggest is initial quality. I’ve seen them last anywhere from one to 15 years, and with all the variables, it just comes down to one question: Are they still good? There are two things to look at. One, are they leaking? If they leak oil, they are probably bad, but not always. Some shocks can exhibit minor signs of seepage, yet they still operate correctly. The second – and the ultimate determining factor – is the bounce test.

With the vehicle sitting on the ground, quickly push down on the suspension and release it. Focus on one spot of the vehicle and watch closely. The vehicle should return to its original height and stop dead. No wiggle, no jiggle – a dead stop exactly where it started. A slight hop above, then a return to original height, means the shocks are worn. If they’re completely wasted, it’ll pogo-stick where it sits.

The bounce test is the only way you can accurately assess performance, and a visual inspection for leaks or worn mount bushings, coupled with age and mileage, can help you determine if it’s time to replace the shocks, or if it’s time to plan for it in the near future. Recognizing the fine line between good and bad shocks can take some experience, and there’s a point where they can begin to adversely affect tire wear and braking distance before any noticeable handling or ride-related symptoms appear, so tire and brake wear should also be considerations when assessing shock condition.

At this point shocks may seem cut-and-dry, but there are some additional topics that may come up when selling them, and it’s good to be prepared with an answer.

Compression/Rebound

When the shock rod travels in, it’s considered the compression stage of operation; when the rod travels back out, it’s considered the rebound stage. The percentage of compression and rebound stage can differ depending on the application of the shock, but normal shock operation is about 25% compression stage and 75% rebound. This allows the suspension spring to react quicker to the road surface for the

best ride.

One of the most common examples of different compression/rebound rates is on the front shocks of a drag car. A 90/10 shock absorber is the most common application here, meaning 90% of the effort to move the shock rod occurs during compression, and it only takes 10% of the force to allow the shock to rebound. On a drag car, under heavy acceleration, this allows the front end to come up easily – shifting the weight to the rear wheels for traction – then slowly allows the suspension to settle to prevent bouncing in the front.

You’ll also see 60/40 or 50/50 percentages depending on the type of racing, performance or ride intended by a manufacturer, and maybe even something different than what I’ve listed here. Generally, you’ll be selling shocks by application, so you won’t have to be concerned about the numbers. But, you never know when someone might ask, so it’s always good to know.

Adjustable Shocks

Many performance shocks are built with adjustable valving, allowing you to change the compression and rebound rates to suit your needs. The adjustments can generally be made by an accessible knob on the side or top of the shock. Some shocks offer adjustment for only one aspect, some offer it for both. This also is the basic idea behind many modern suspensions that offer adjustable dampening, such as luxury or sport mode options. Instead of a manual adjustment to change compression and rebound rates, the adjustment is performed by a built-in electronic actuator that receives its signals from the vehicle control unit.

Measuring Shocks

Sometimes it becomes necessary to measure the required length of a shock absorber for a vehicle that’s been raised or lowered, changing the suspension travel. This is especially common for lifted trucks. If the question comes your way, it’s not hard to do. The specs you will need are compressed and extended height, but there are three measurements to take to get them.

Park the vehicle on level ground, then first measure the static height, which is simply the distance between the upper and lower shock mounting points. For this to be an accurate measurement, you’ll have to remove the shock. Next, with the vehicle still on level ground, measure the distance between suspension bump stop and the contact point for the bump stop. Subtract this from the static height and you have your compressed height.

To get extended height, jack up the vehicle so the wheel is off the ground, support it with a jack stand (for safety), then measure again between the upper and lower shock mounting points.

Load-Supporting Shocks

Many traditional shock absorbers are designed to assist the suspension when towing or hauling heavy loads. These are available as both air- and spring-assisted types. They are not designed to increase the load-carrying ability of a vehicle, but rather to help maintain the proper ride height and prevent bottoming out with a heavy load. Spring-assisted shocks offer a consistent load assist without affecting ride quality, and air shocks are adjustable to handle a wider range of varying loads but are designed to have the additional pressure released when the load is removed so the ride height returns to normal.

Selling Struts

When a customer comes in and wants to buy struts, the first thing that should come to your mind is what do they really need? Do they need a complete strut assembly? Or do they just need a strut housing? Maybe they only need shocks and just have their terminology wrong. Once you determine they indeed need struts, most likely you will direct them to a quick strut.

As I mentioned earlier, we always used to rebuild struts. It never seemed like a problem to me, but then again, I was used to it, and broken coil springs were never much of a problem. Then, all of a sudden, coil springs started breaking frequently, and some cars were known for it. When it came to a repair, it was common to find the shock leaking, and since you had everything apart, it didn’t make sense to replace the spring with an old shock. Then you found that the strut mounts were worn, so you ordered those too.

No matter how you looked at it, you had a lot of parts and a lot of labor involved. Then came the quick-strut: a fully assembled strut with new spring, shock, strut mounts and everything, ready to bolt in. On vehicles that needed everything, this proved to be an efficient solution.

Do I use them all the time? No. They’re not available for all vehicles, and in some cases on certain performance vehicles, the OE equipment is the best and only option for quality and customer satisfaction. You may have to do it the old-fashioned way.

But for many applications – especially on older high-mileage vehicles – if the shock is completely worn out, you can bet the rest of the components are too, and it just makes sense. Sure, a lot of technicians like them because it makes the job much quicker and you don’t have to fight with a coil spring, but it more importantly gives you a big advantage in selling to DIYers, because most likely they don’t have the tools to compress the spring.

Some final extras are sway-bar links, which often attach to a bracket on the strut housing. They’re often hard to remove and it’s probably a good time to replace them too. Shock absorbers should come with all needed hardware, and some shocks and struts are bushing-mounted at the bottom. As with any suspension bushings, these should be tightened with the vehicle at ride height to prevent premature wear of the bushing.