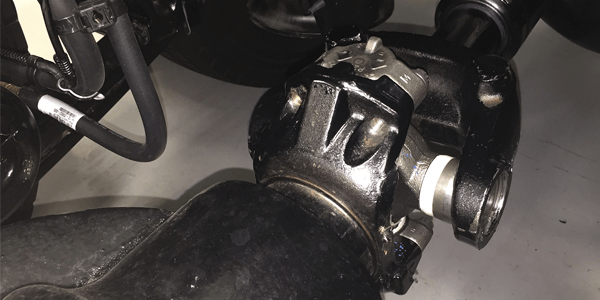

SKF recently announced the availability of an online video, demonstrating how to inspect and replace a u-joint on a commercial truck. The video highlights using SKF u-joints to replace a rear driveshaft u-joint on a 2017 Freightliner Cascadia truck.

SKF recently announced the availability of an online video, demonstrating how to inspect and replace a u-joint on a commercial truck. The video highlights using SKF u-joints to replace a rear driveshaft u-joint on a 2017 Freightliner Cascadia truck.

“We’re excited to offer this newly released video, giving technicians the opportunity to see a complete inspection and replacement of a u-joint on a heavy duty truck application,” said Brian Jungmann, Marketing Communications Manager, SKF. “Through videos like this offered on our YouTube channel skfpartsinfo.tv, SKF is aiming to help fleet technicians deliver reliable performance and maximum service life, ultimately minimizing truck down time.”

The video – available here – provides fleet technicians with the details needed to successfully inspect and replace a rear u-joint. It begins by outlining the tools needed followed by an overview of a detailed inspection. The video then provides step-by-step instructions for disassembly and reassembly.

SKF Universal Joints meet or exceed original equipment specifications. Each part is precision manufactured to provide reliable performance and maximum service life. The SKF Brute Force universal joint is a high performance part that is designed for higher horsepower and torque applications and extreme conditions. They are available in greasable and non-greasable versions.

For more information about SKF and its complete line of u-joints, contact your local SKF representative, visit www.skfusa.com/ujoints, call 800-882-0008 or visit the SKF e-catalog at www.SKFpartsinfo.com. You can also follow SKF on Twitter @skfpartsinfo or subscribe to our YouTube channel at www.skfpartsinfo.tv.