There are many bedliners available on the market today, ranging from drop-in bedliners to sprayable products. If you opt for a two-component sprayable option, you’ll want to make sure you take the necessary steps to get the most durable, protective finish for your job. Proper preparation is key whether you are applying product to a pristine surface or making a repair to an existing one.

When preparing or repairing an area, begin by removing any loose material present. Then clean and degrease the surface. Note: Cleaning and degreasing also holds true for new panels to ensure that all organic and petroleum-based contaminants are removed for proper adhesion. Once your work area is cleaned and degreased, below are general sanding guidelines for various substrates, keeping in mind that there may be slight variations in recommendations by the bedliner manufacturer:

Surface Types and General Sanding Guidelines*:

| Surface Type | Sandpaper Grit |

| Bare Metal | 80 – 180 |

| Aluminum/Galvanized | 180 |

| Rigid Plastics (ABF, SMC, Fiberglass) | 120 – 180 |

| Flexible Plastics (TPO, EDPM, PP) | 180 – 320 |

| OEM E-Coat | 180 |

| Paint or Previously Prepared Bedliner | 220 |

*Be sure to follow your bedliner manufacturer’s technical data sheet for detailed instructions.

Types of Surface Preparation Products:

Once the surface has been properly abraded, reclean the area before applying bedliner (all substrates). For larger exposed areas of bare metal or new panels, a full two-component primer system such as an epoxy primer, is recommended before applying bedliner. Some epoxy primers may be applied directly over surface rust and can also be applied wet-on-wet, thereby eliminating the need to sand the epoxy primer prior to your bedliner application. In general, epoxy primers also improve intercoat performance and further extend the life of the protective bedliner coating.

If you are applying bedliner to a painted metal surface and experience “rub through” areas after sanding, it is recommended that you apply an etch primer containing phosphoric acid, which will create an anti-corrosion barrier, help to prevent rust from forming, and provide a suitably primed substrate for the bedliner to bond to. Applying an acid etch primer with phosphoric acid will also promote paint adhesion on difficult substrates like galvanized steel and aluminum. Some acid etch primers can also be directly top-coated after application, thus saving an additional sanding step before your bedliner application.

For rigid or flexible plastic components like bumpers or side cladding, or hard to reach painted areas that are difficult to sand such as internal corners, an adhesion promoter is recommended before applying the bedliner, to ensure proper adhesion.

Application of a Two-Component Bedliner System:

Once your surface has been properly prepped, it is time to select your bedliner and type of application method. Many manufacturers offer multiple kit sizes and colors – for example, black, white, and tintable kits, which can be used with solvent-based toners from a mixing bank.

How much product is needed for my application?

Although products may vary from one manufacturer to another, one should estimate that it takes one activated quart of material per every running foot of coverage at approximately an 18-mil build (2 coats).

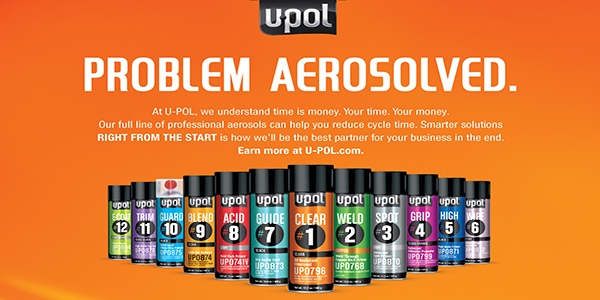

For smaller applications, some manufacturers offer convenient aerosols, or liter and quart kits, which can be used on a multitude of areas, including roll bars, running boards, grilles, wheels, or fender flares.

What’s the best way to apply it?

Generally, most bedliners can be applied with an applicator gun, a roller, brush, or an aerosol. Some manufacturers include the application equipment as part of their two-component kits, or sell guns and rollers separately. In the end, the product choice and application method are yours, and depends on your application preference. View a demonstration here.