Since 1934, Blue Streak® by Standard® has been known for quality and durability. The brand’s original products included points, condensers, caps and rotors, among others. Today, the Blue Streak® by Standard® brand is back with a new line of heavier-duty, longer-lasting ignition coils. To see what makes Blue Streak® ignition coils superior, here’s a visual comparison conducted by Standard Motor Products Inc. (SMP) on a sampling of Blue Streak® ignition coils against one of the leading OE coils.

Blue Streak® vs. OE Coil Comparison

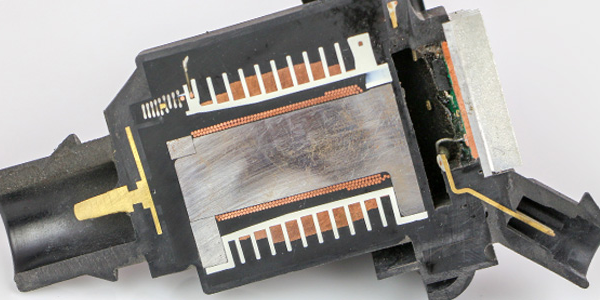

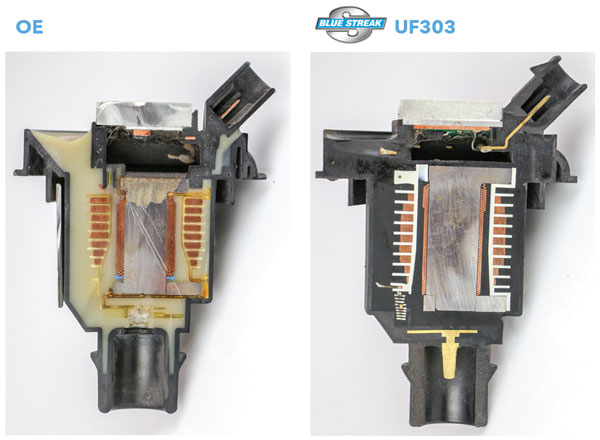

One noticeable difference is that the OE ignition coil tested on the left is potted using a “yellow” epoxy system. When compared to common “amber/yellow” epoxy systems, the Blue Streak® “black” epoxy system features nearly 40% higher insulation resistance to voltage breakdown.

But there are more differences when you look closer. For example, the OE ignition coil tested featureseight primary winding sections. With 10 primary winding sections, the Blue Streak® design reduces the height of each section’s winding to decrease the risk of breakage between sections.

Additionally, the OE ignition coil tested features an uneven number of winding turns. The Blue Streak® barrel winding distribution precisely reduces the number of turns in the first and last two sections to reduce the voltage gradient. When combined with a higher G2 insulation grade, the Blue Streak® winding distribution lowers the risk of breakage within the winding.

Blue Streak® Outperforms the OE

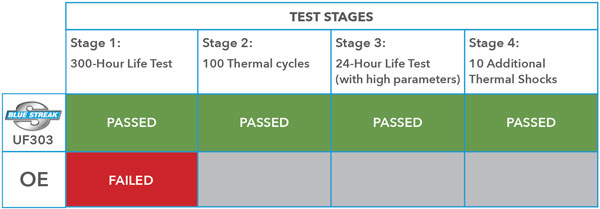

All Blue Streak® ignition coils undergo extensive measurement and life testing, in addition to a full range of environmental analysis that includes thermal shocks, thermal cycling and vibration tests, just to name a few. Here’s how the Blue Streak® UF303 Ignition Coil tested against the OE:

Testing Takeaways

- The two OE coils tested short-circuited after 68 hours and 140 hours, respectively.

- The two Blue Streak® coils tested passed the 300-hour life test as well as 100 thermal cycles, a 24-hour life test and 10 thermal shocks.

- Compared to the OE, the two Blue Streak® ignition coils tested had a 9% higher spark energy and 18% higher secondary voltage, which leads to better combustion of fuel mixture and reduced exhaust-gas discharge.

Made to Stand the Test of Time™

All Blue Streak® ignition coils are designed, manufactured and tested at SMP’s IATF 16949 and ISO 9001-certified facility in Bialystok, Poland. Spanning 108,400 square feet, the facility serves as a basic design and engineering center for Blue Streak® ignition coils. The facility employs lean manufacturing methods such as the 5S philosophy and features a vertically integrated manufacturing process with multi-spindle winding, injection molding, potting, curing and welding.

At the end of the day, the parts that leave SMP’s facility are manufactured for superior performance and durability. In fact, all Blue Streak® ignition coils are laser-etched with the Blue Streak® logo and are backed by a limited lifetime warranty. To learn more about the new Blue Streak® ignition coils, visit StandardBlueStreak.com and stop by booth 4226 at this year’s AAPEX show.

This article was sponsored by Blue Streak® by Standard®