Many people have an “if it ain’t broke, don’t fix it” mentality. In addition, most timing belts are hidden under an engine cover, so they’re “out of sight, out of mind.” It’s no wonder many people don’t think about replacing their timing belt.

It’s important to help your customers understand the importance of the timing belt and why it’s a good idea to replace one. But first, let’s review two fundamental engine designs.

Interference vs. Non-Interference Engines

Some customers may be familiar with the concept of an “interference” or “non-interference” engine. Basically:

- Interference engines are designed in a way that the valves are perfectly timed with the pistons. If the timing is off, they can collide. Interference engines have become more common as compression ratios have risen.

- Non-interference engines are designed so that the pistons and valves won’t ever make contact with each other – no matter what happens with the timing belt. This design was more common when engines used lower compression ratios.

Most customers won’t know which design their engine uses. And most aren’t aware of the damage that can be caused when things go wrong.

The Importance of a Timing-Belt Replacement

To get a customer to understand the importance of a preventative timing-belt replacement, explain what happens when a timing belt breaks.

When a timing belt breaks, the camshaft stops turning. This leaves some of the engine valves stuck open. However, the pistons will keep moving. In an interference engine, they will hit the valves that are stuck open. This can bend or break valves and can possibly damage the piston and cylinder head. In a nutshell, a broken timing belt leads to serious engine damage.

Proper preventative maintenance, in many cases, will cost much less than repairing the damage caused by a broken timing belt.

Don’t Forget to Mention the Water Pump

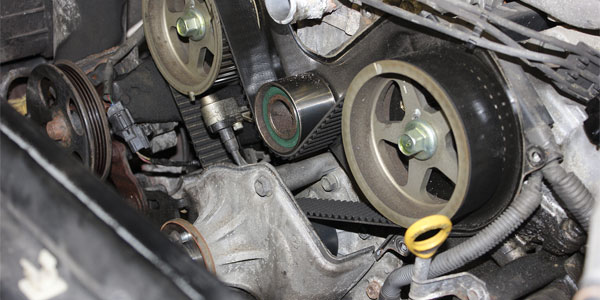

Replacing the timing belt is pretty labor-intensive. There are many components that your customer should consider replacing at the same time:

- Water pump and coolant

- Serpentine belt (or drive belts), tensioners and idler pulleys

- Camshaft and crankshaft seals

To prevent duplicate labor and cost, the water pump and related timing components should be replaced at the same time as the timing belt. They might not be completely worn out, but they will wear out long before the timing belt needs to be replaced again.

Hopefully your customer won’t need new camshaft and crankshaft seals. However, it’s best to encourage them to buy a set. It’s a lot easier to have them on hand if they’re needed.

Recap

It’s natural for a customer to be a bit skeptical about needing to replace their timing belt when it isn’t broken yet. However, it’s worth taking the time to make sure the customer understands what can happen if they don’t replace it within the recommended maintenance period.

This article was sponsored by GMB North America, Inc. For more information, please visit our website at www.gmb.net