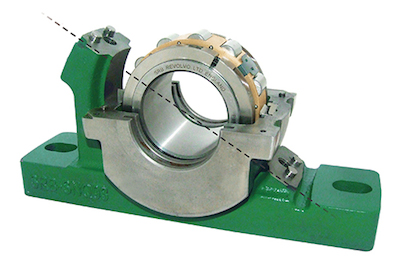

NORTH CANTON, Ohio — With the first-of-its-kind angled support pedestal, Timken Revolvo Quick-Fit split cylindrical roller bearings now make installation even easier for change-outs where access is limited, according to the company. The totally new design can reduce installation time up to 90 percent, and in many cases, one person can complete the installation, Timken says.

Timken launched Quick-Fit housed units in Europe earlier this year for SN/SD configured housings and is now introducing the line in North America with SAF-configured housings. First produced by Revolvo in 2011, the angled pedestal eliminates the need to remove the drive and lift the shaft to replace a solid bearing or to replace the support pedestal of a split bearing.

“Quick-Fit changes the game when it comes to replacing bearings in challenging-to-reach locations,” said Cory Shaw, business manager of the housed units business at Timken. “The outer support is split at an angle, allowing it to be slid under the shaft during initial replacement. This makes retrofitting mounted bearing units much faster and easier in applications like fans, conveyors, crushers, kiln drives and marine propulsion shafts.”

The complete line of Revolvo split-to-the-shaft cylindrical roller bearing housed units allows the bearing to be assembled around the shaft without requiring access to the shaft ends. Once installed, maintenance personnel can easily remove support caps and housing components for quick visual inspection, saving maintenance time. The seven concentric seal designs provide customized options to meet harsh environments requirements, which can extend operational life beyond competitors’ designs. Widely used by mining, power generation, food and beverage, pulp and paper, metals, cement, marine and waste-water operators, these units can quickly reduce maintenance costs and increase plant profitability.