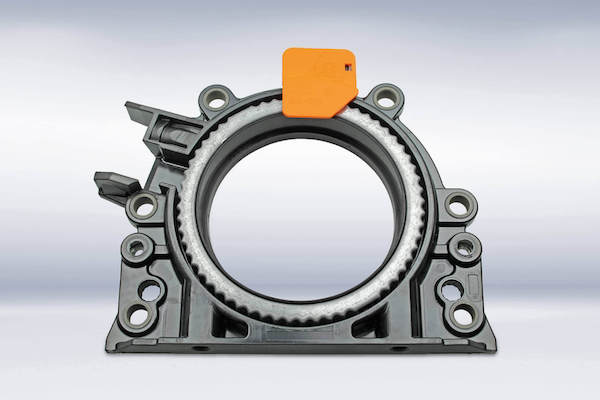

The importance that small parts play in ensuring operational reliability cannot be underestimated. This is why all MEYLE parts provide the highest quality, no matter the size of the component. And this is how MEYLE helps auto repair professionals and car drivers avoid a lot of trouble and save money. An excellent example of small parts that have a major impact on the overall system are crankshaft sealing flanges used to protect the engine. MEYLE offers PTFE seal modules to fit over 2,000 different vehicle applications: these come equipped with an integrated trigger wheel.

Sealing flange modules are important to ensure effective sealing at the engine crankshaft. They are also used to capture the engine speed and crankshaft position, and to determine both the injection and the ignition point controlled by the engine timing unit. The use of low-grade parts would result in early component wear – resulting in engine start issues, oil loss and odour emissions. This is why MEYLE offers to repairhops field-proven crankshaft sealing flanges made from plastic distinguished by their superior wear resistance.

Sealing flange modules are important to ensure effective sealing at the engine crankshaft. They are also used to capture the engine speed and crankshaft position, and to determine both the injection and the ignition point controlled by the engine timing unit. The use of low-grade parts would result in early component wear – resulting in engine start issues, oil loss and odour emissions. This is why MEYLE offers to repairhops field-proven crankshaft sealing flanges made from plastic distinguished by their superior wear resistance.

Hamburg-based manufacturer MEYLE supplies 16 different sealing flange modules designed to OE specifications to fit VAG models. They cater for over 2,000 vehicle applications, including the VW Crafter and Audi models A1 to A6. The ready-to-fit modules come pre-assembled and feature a dynamic and a static seal as well as a trigger wheel. Repair workshops and their customers benefit from the superior material quality of MEYLE ORIGINAL sealing flange modules.

MEYLE workshop advice: The automotive specialist recommends that the sealing flange module be inspected and, if necessary, replaced during the regular clutch inspection which is due after 80,000 to 100,000 driven kilometers. In order to prevent oil leaks, engine start issues or damage to the crankshaft, the following rules should be observed when performing repair work:

1. ensure the crankshaft is not damaged and the mounting face is clean;

2. remove any mounting sleeves or transport locks only immediately prior to the assembly of the part;

3. do not remove or rotate the trigger wheel and

4. do not use any mounting grease.