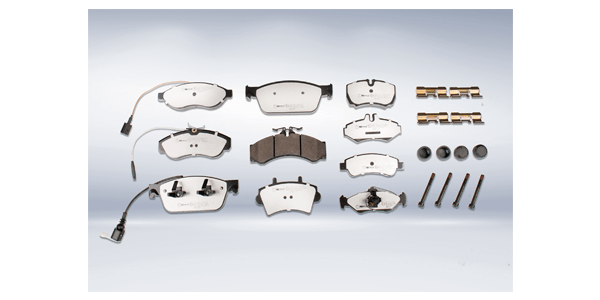

HAMBURG — German auto parts manufacturer MEYLE now offers MEYLE PD brake pads with refined friction material mix to fit a wide range of van models, including the Mercedes Sprinter, VW Crafter and Ford Transit, the company says.

Brake pads used on vans are subject to heavy load and stress levels which often results in early part wear and reduced braking performance. Plus: There is truth in the claim “time is money”: every workshop visit means costly van downtime for a fleet operator. This is why the new generation of MEYLE-PD brake pads for vans features a highly wear-resistant friction material mix designed to offer extended brake pad life. In the best of cases, vans equipped with the new rugged MEYLE-PD brake pad will only come to the workshop for routine vehicle inspection rather than unscheduled brake replacement.

Brake pads used on vans are subject to heavy load and stress levels which often results in early part wear and reduced braking performance. Plus: There is truth in the claim “time is money”: every workshop visit means costly van downtime for a fleet operator. This is why the new generation of MEYLE-PD brake pads for vans features a highly wear-resistant friction material mix designed to offer extended brake pad life. In the best of cases, vans equipped with the new rugged MEYLE-PD brake pad will only come to the workshop for routine vehicle inspection rather than unscheduled brake replacement.

The new MEYLE-PD brake pads for vans feature triple-layer damping shims attached to the brake pad backing using a special adhesive with advanced damping properties. These shims are designed to neutralise vibration and prevent the infamous brake squeal. To reduce the amount of noxious substances released into the environment as a result of brake pad wear, the newly formulated MEYLE-PD brake pad for vans does not employ copper or any other heavy metal additives – neither does the MEYLE-PD brake pad for passenger cars.

The new MEYLE-PD brake pads have testified to their excellent braking behavior and friction coefficient throughout extensive testing and are ECE R90 type-approved. As of now, MEYLE-PD brake pads for vans are available for the Mercedes Sprinter, VW Crafter, Citroën Jumper, Opel Movano, Renault Master, Ford Transit and Iveco Daily. The range of MEYLE-PD brake pads for vans will continue to grow.