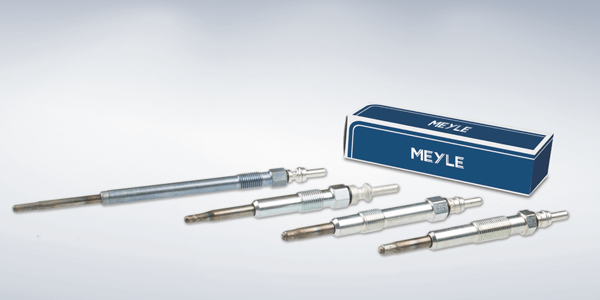

MEYLE AG provides around 130 MEYLE-ORIGINAL glow plugs for all standard applications. These parts, manufactured completely in accordance with OEM specifications, ensure that MEYLE covers around 90 percent of all diesel vehicles throughout Europe. In addition, the Hamburg manufacturer also provides around 60 glow-time control unit kits in MEYLE-ORIGINAL quality which include the control unit and the appropriate glow plugs.

Glow plugs extend into the cylinder of the diesel engine and heat up to temperatures of up to +1000°C. This extreme heat is required to ensure the cold start of a diesel engine even in winter, with icy temperatures of up to -40°C. To prevent defects and wear, the MEYLE-ORIGINAL glow plugs are produced in accordance with OEM specifications – which includes the use of heat-resistant metal and twin heating coil technology. As a result, MEYLE-ORIGINAL glow plugs have optimum thermal transfer and high insulation capacity against leakage currents or flashovers. In addition, the inside of the glow plug is anti-hygroscopic on account of a special rubber seal – meaning it does not absorb any moisture which in turn prevents corrosion inside the plug. Use of top quality materials and optimally tuned components ensure the specified afterglow temperature of MEYLE-ORIGINAL glow plugs can be precisely maintained. This reduces exhaust emissions considerably, and is good for the environment.

Glow plugs should be replaced every 80,000 to 100,000 kilometers to prevent malfunction due to wear. Worn glow plugs may cause serious starting problems especially during cold temperatures in the autumn and winter months, and lead to the engine not running smoothly, causing an increase in pollutant emissions and smoke development.

There are many reasons why a glow plug does not function properly: in addition to aging-related wear, incorrect installation, a defective control unit or inadequate processing of glow plugs may be reasons for defects. This can result in deformed, broken or burst glow plugs which may give rise to expensive consequential damages. For example, it may not be possible to remove the glow plugs or – in the worst case – parts of the glow plug may enter the cylinder and cause damage to it.

MEYLE Technology Know-how: An overview of the specifications for MEYLE-ORIGINAL glow plugs:

| Specification | Benefits |

| Corrosion-resistant connection | Ensures reliable current flow |

| Twin heating coil technology | Short pre-glow times, cold start up to -40°C, optimum afterglowing |

| Optimally tuned insulation properties of materials used relating to temperature, installation space and hygroscopy (moisture absorption) | Excellent thermal transfer, not hygroscopic, insulation against leakage currents and flashovers |

| Top quality internal seals | Prevents air contact and hygroscopy, preventing coil corrosion |

| Fully automatic laser welding technology | Constant, reliable connections between heating and control coils |

| Short heating coils (in the glow plug tip) | Quick start possible (even at low temperatures) |

| Use of top-quality individual components/materials | Afterglow temperature can be maintained after cold start as a result of optimally tuned materials. This considerably reduces exhaust emissions. |

| Developed and manufactured in accordance with OEM specifications | MEYLE-ORIGINAL glow plugs – with OE precision |

| Environment-friendly and energy-saving production, free of chromium VI | Not hazardous to the environment during production and disposal |

| 100 % testing | Certified product |

MEYLE Workshop Tip: Glow plugs should be replaced every 80,000 to 100,000 kilometers. MEYLE also recommends that all glow plugs be replaced at the same time to prevent subsequent repair work. The control unit should also be checked when replacing the glow plugs. And when replacing the control unit, all glow plugs should also be replaced – this prevents a new control unit being damaged by a defective glow plug.