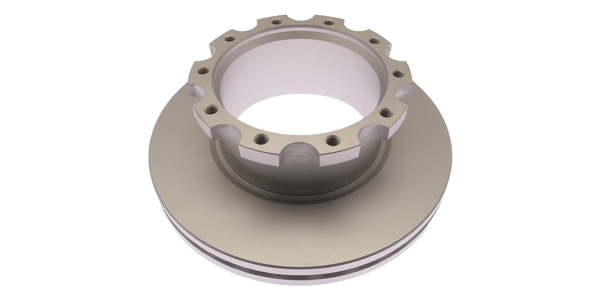

Raybestos has added four new part numbers for air disc rotors to its specialty rotor line, and the company said it plans to release additional part numbers later this year.

“We’re thrilled to continue expanding our air disc rotor offering to pair with our already strong air disc-brake-pad offering,” said Sam Rusenovich, director of sales – commercial vehicle and customer experience, Brake Parts Inc. “Our air disc products are specifically designed to handle the demands of Class 7 and 8 vehicles by providing better stopping power and unmatched durability. All of our air disc products meet or exceed original design and performance requirements.”

Raybestos air disc rotors are designed to meet or exceed OE fit, form, function and SAE metallurgy, according to the company.

“This discipline in design allows for better endurance under extreme temperatures and vehicle load,” the company added in a news release.

All rotors are 100% coated with Grey Fusion 4.0 technology for corrosion resistance. Raybestos air disc rotors are qualified by the new SAE J3080 crack-test procedure for air disc brakes, written specifically for these applications in 2018. Raybestos not only passed this rigorous test, but also far exceeded its stringent requirements, the company noted.

Raybestos also has a complete offering of medium duty products developed for demanding work environments and created with fleets in mind. For more information on the complete line of Raybestos commercial-vehicle products, visit www.raybestos.com.