All friction linings have a minimum thickness specification that indicates when the pads or shoes are “worn out” and need to be replaced. The exact number will vary somewhat from one application to another, but generally speaking the linings need to be replaced when the thickness of the remaining friction material is 1/8 inch (3 mm) or less.

All friction linings have a minimum thickness specification that indicates when the pads or shoes are “worn out” and need to be replaced. The exact number will vary somewhat from one application to another, but generally speaking the linings need to be replaced when the thickness of the remaining friction material is 1/8 inch (3 mm) or less.

The minimum thickness specification leaves a little wiggle room for replacement because the linings probably have a couple thousand miles to go before they go away entirely. Even so, replacement should be done as soon as possible. Why? Because thin brake linings are potentially dangerous linings. The thinner the lining, the greater the risk of the friction material cracking and/or delaminating from its backing plate. This could cause a loss of braking friction and possibly brake failure.

One of the reasons for National Car Care Month is to raise awareness of vehicle maintenance and service needs. Most people have no idea what condition their brakes are in unless their vehicle is experiencing an obvious brake problem such as pulling to one side when braking, brake noise, increased pedal effort, pedal pulsation or a brake or ABS warning light on the instrument panel.

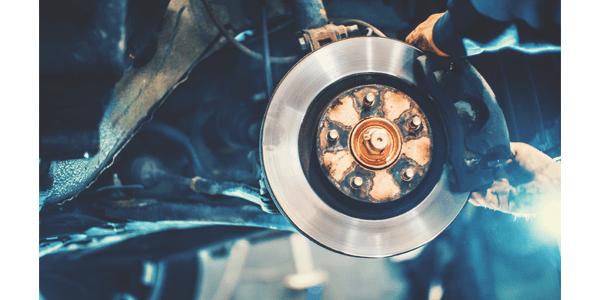

The thickness of many disc brake pads can be determined by a quick visual inspection, often with the wheels in place if the wheels are an open spoke design. Removing the wheels and actually measuring the thickness of the inner and outer pads is the more accurate method, especially for checking the inner pad, which may be difficult or impossible to see with the wheels in place.

Checking the thickness of the rear shoes on a vehicle with drum brakes requires more disassembly. The wheels and drums have to come off to check the linings.

One clue that often indicates worn brake linings on vehicle with disc brakes (with the wheels in place) is a very rough appearing rotor. Heavy scoring or grooving on the rotor face often indicates the pads also are heavily worn and may need to be replaced.

If a vehicle is experiencing a pedal pulsation, uneven rotor wear will be the underlying issue and possibly worn pads, too. The appearance of dark discolored heat spots on the rotor face are a clue to uneven rotor wear and the need for brake service.

Brake linings also may need to be replaced because they have been contaminated with grease or oil from a leaky wheel bearing or axle seal. Brake fluid seeping out of a caliper or wheel cylinder also can contaminate the linings. Contamination will affect the friction characteristics of the linings, which in turn may cause the brakes to grab or pull to one side when the brakes are applied.

If a customer plunks a set of pads or shoes on your store counter that are obviously contaminated with grease, oil or brake fluid, new linings should not be installed until the source of the contamination has been identified and fixed. Your customer may need a new or remanufactured caliper or wheel cylinder or a wheel bearing or axle seal.

Another reason to replace friction linings is to upgrade braking performance. Original equipment brake linings are fine for everyday driving, but may not be the best choice for performance driving, racing or hard-use applications such as police vehicles and taxis (including some Uber drivers). More demanding applications may require a premium grade or specialty friction material that can safely handle higher temperatures without fading. Follow your brake supplier’s recommendations for selecting upgrade linings. The quality and performance characteristics of brake linings should never be downgraded to save a customer money. Replace same with same or better.