The most often replaced part on vehicles with manual transmissions is the clutch. The clutch is a wear item and will eventually wear out.

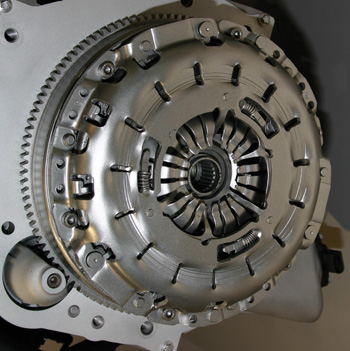

The clutch is bolted to the flywheel on the back of the engine, and clamps the clutch disc against the flywheel when the clutch is engaged. When the clutch pedal is depressed to disengage the clutch, the pressure plate pulls away from the flywheel and disc, releasing the disc.

The clutch is bolted to the flywheel on the back of the engine, and clamps the clutch disc against the flywheel when the clutch is engaged. When the clutch pedal is depressed to disengage the clutch, the pressure plate pulls away from the flywheel and disc, releasing the disc.

Most vehicles have a diaphragm spring clutch, but some older vehicles have a coil spring clutch. The clutch is actuated by a cable, mechanical linkage or hydraulic cylinder. Leaky piston seals and hoses are common problems with the clutch master and slave cylinder. Replacing both is recommended on high-mileage vehicles if either has failed.

The clutch disc is the flat plate with friction facings on both sides that goes between the clutch pressure plate and flywheel. Over time, the facings wear and reduce the clutches ability to hold under load — especially if the driver “rides” the clutch. Slipping or chattering (jerky engagement) also can be caused by glazed or burned facings, or oil contamination. Oil leaks must be fixed before the new clutch is installed. A “pilot tool” is required to center the disc when it goes in.

If the clutch is slipping under load, or chattering or grabbing when it engages, a new clutch may be needed. Because of the labor required to replace a clutch, a clutch kit that includes a new clutch pressure plate, clutch disc and release bearing are recommended. A kit eliminates the risk of mismatching parts from different suppliers, and reduces the risk of future clutch problems down the road.

For towing or performance applications, larger, stronger clutches are available to upgrade driveline reliability and performance. Recommend upgrading to a performance clutch if your customer has had repeated clutch failures or has a modified performance engine.

Another clutch component used on many rear-wheel drive vehicles is a pilot bearing or bushing. Located in the end of the crankshaft, the pilot bearing supports the transmission input shaft. Failure can cause noise or clutch release problems. Replacement is recommended when servicing the clutch or flywheel.

The flywheel may have to be resurfaced if it is not smooth and flat. It should be replaced if cracked. Some engines have a “dual mass” flywheel, which is like two flywheels in one. A dual-mass flywheel dampens engine vibrations and cushions clutch engagement. If the flywheel is damaged or the springs inside a dual-mass flywheel have failed, the flywheel must be replaced. A less expensive solid flywheel can replace a dual-mass flywheel, but may increase drivetrain harshness and vibration.