By Bill McKnight

Team Leader – Training

MAHLE Aftermarket Inc.

Thermostats have been an important component in automotive internal combustion engines for almost a century. Thermostats were originally incorporated to speed engine warm-up and reduce cylinder ring wear. Today, thermostats play an important role in increasing engine combustion efficiency and reducing emissions. To accomplish that task, thermostat functions are controlled by the engine’s electronic control unit (ECU), ensuring precise regulation of temperature based on the engine’s loads.

Basic mechanical thermostat operation

The combustion process in a passenger car engine runs optimally at an operating temperature of approximately 230 degrees Fahrenheit. However, in older engines the engine temperature was kept below this ideal temperature level to prevent component damage. Since an engine requires a certain power reserve, especially when operating at full load, conventional thermostats start to open at an engine temperature of approximately 110 degrees Fahrenheit by opening the coolant circuit.

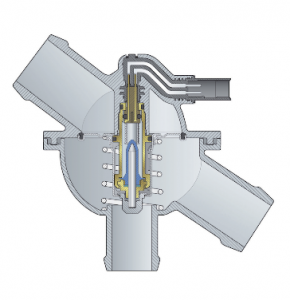

The most basic type of thermostats is a by-pass valve thermostat. These have a sensing element containing a wax and aluminum mixture that expands when heated. When the engine is cold, the wax is solid and as it expands, the sensing element slides, opening a valve and allowing coolant to flow to the radiator. A tension spring presses against the sensing element and closes the valve when the operating temperature falls below the opening level of the thermostat. This process may occur multiple times a day, especially in colder climates.

This technology — which still serves reliably to this day — has been in use for decades, but the open temperature setting of the thermostat can only be adjusted slightly by changing the wax compound.

Mapping the engine’s optimum performance

New technologies are pushing engine efficiency and combustion quality ever closer to optimum operating conditions. As we push the engine closer to the desired 230-degree range to improve both emissions and fuel economy, we need a more advanced thermostat technology.

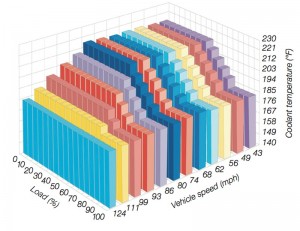

An electrically assisted (also called “map-controlled”) thermostat provides broader and faster operation than traditional thermostats. In addition to the mechanical function of the wax element, electrically assisted thermostats incorporate an electric heater within the sensor. This heater is controlled by the vehicle’s ECU, which receives information on the speed and load conditions of the engine. It uses this information to regulate the temperature of the coolant. A data set, or “map,” is stored within the ECU to govern when and how heat is added to ensure optimum engine performance.

Consequently, the thermostat can influence the temperature considerably more quickly, allowing the engine to operate in various load and operating conditions within the corresponding optimum range.

This level of temperature regulation yields several benefits:

- Optimum combustion due to increased cylinder wall and component temperatures

- Reduced fuel consumption due to reduced viscosity of the engine oil and consequently reduced frictional loss

- Lower pollution emissions due to improved combustion

- Improved power output at full load due to reduced coolant temperature

- Increased comfort due to higher coolant temperatures and, as a result, an improved interior heating performance

How an electrically assisted thermostat works

In standard operation, an electrically assisted thermostat functions in the same manner as a conventional thermostat — just at a higher engine temperature. Coolant flows around the wax of the thermal expansion element. As the temperature rises, the expansion material melts, increasing in size and moving a piston, which in turn increases the flow volume of the coolant. If the temperature drops, a spring pushes the piston back to its starting position, reducing the flow rate of the coolant or closing the coolant circuit altogether.

(Fig. 2A)

Under partial load conditions (city driving), the thermostat stabilizes the engine at a higher temperature by staying closed longer to obtain benefits such good power response, lower emissions and reduced friction (with a corresponding reduction in fuel consumption).

When under a sudden, heavy load, an additional heat source comes into play with the map-controlled thermostat. Once the conditions of the stored operating map have been fulfilled, a heating resistor integrated in the expansion material is enabled by the engine management system. This additional heat source allows the wax to expand quicker, opening the thermostat fully regardless of actual coolant temperature, so the coolant flow is increased; immediately allowing the engine to operate within the optimum temperature range without danger of overheating.

Since the electric thermostat is controlled by the engine computer and mapped to driving conditions, when the sudden heavy demand is removed, the current is shut off to the electric heating unit and the thermostat again acts like the traditional wax unit with a fully open temperature of approximately 230 degrees Fahrenheit. These actions can happen many times a day, especially if you were driving up and down in the mountains where the engine and cooling system would experience heavy demand going up a grade then may cool as much as 30-50 degrees Fahrenheit going down the other side. The beauty of this concept and design is that it operates completely unnoticed by the vehicle operator and continues over the life of the thermostat with no required service.

Important considerations for the aftermarket

As is the case with conventional thermostats, electrically assisted thermostats are not subjected to materials wear; they are maintenance-free and designed to last for the entire engine service life. However, external factors such as the use of low-grade coolant and failure to regularly service the coolant can lead to material failure. Other possible causes of failure include previous damage caused by thermal overloading or contamination due to work carried out on the cooling system, e.g. when replacing the coolant or water pump, the cooler, the coolant hose, timing belt, or V-belt.

It is important for the technician to remember that the Map-controlled thermostat is only part of a more complex cooling system consisting of coolant passages in the engine, a coolant mixing chamber around the thermostat, coolant hoses, a radiator, electric fans and the actual coolant. When replacing faulty parts in the cooling system, thermostats and/ or integral thermostatic housings should also always be replaced at the same time, because any loss of functionality or even complete failure can have severe consequences—including engine damage.

About Bill McKnight:

Bill McKnight is Team Leader-Training for MAHLE Aftermarket Inc. He formerly served as the Director of Training and as the Director of Marketing for Clevite bearings. McKnight also represents MAHLE Aftermarket Inc’s bearing and piston ring products at NASCAR, NHRA drag racing, diesel motorsports, Formula Drift and most other motorsports venues. He is a PERA and AERA member and has made numerous presentations for both organizations.