Electric-assisted power steering (EAPS) has been around in some form or another on production vehicles since 1990. The Acura NSX was the first, but as of 2011 the market had grown to more than 50 percent of the new-car market. This shift is due in part to the popularity of hybrids, as well as the increasing computerization of the average vehicle. In the aftermarket, we have become familiar with many of the electric components that work in conjunction with the traditional hydraulic power steering system, but the all-electric rack and pinion is still fairly new to us. The hydraulic rack and pinion is slowly giving way to a fully electric design, for several reasons.

Eliminating the hydraulic portion of the mechanism allows the manufacturer more options in an ever-smaller engine compartment. Without a pump, fluid reservoir and the associated plumbing, the OEMs save weight, space and even the maintenance schedule of power steering fluids. Eliminating the belt-driven pump also reduces the engine load, in some cases recovering a few horsepower. This can equate to great savings on fuel economy over the long-term, sometimes up to 3 miles per gallon. The horsepower gain also is attractive to street rod and custom car builders, who were early adopters of the electric power steering rack as a way to save space and eliminate clutter under the hood. Finally, it is an optimal choice for mid-engine cars, since the steering gear can be easily located away from the engine, connected by wiring instead of fluid lines.

The current crop of hybrids, with their stop-start technology, still require power steering assist even when the engine is in “stop mode.” Low-speed city driving, and parking maneuvers require the most assist, but are the conditions when a hybrid is likely running off electric power only. A hydraulic rack and pinion would require a constant supply of fluid, normally provided by an engine-driven pump. The technology exists for electric-driven fluid pumps, and has been used in other vehicles, but the fully electric rack and pinion seems to be the preferred method of providing power steering assist.

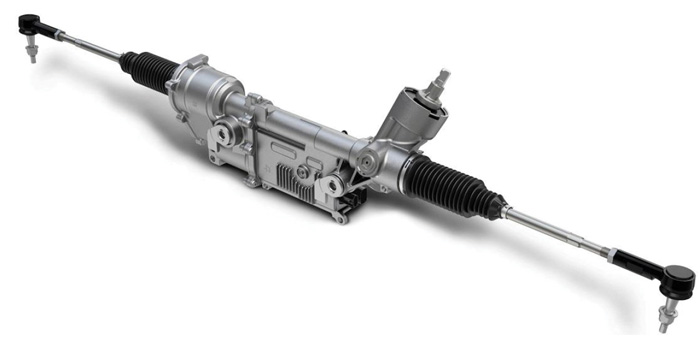

An electric rack and pinion looks very much like its hydraulic brother, with the power coming from an electric motor rather than fluid pressure. The motor may be pinion-mounted, located at the input shaft, or rack-mounted, parallel to the body of the steering gear itself. A third design uses a column-mounted motor under the dash, separate from the rack and pinion itself. All three designs rely on sensor inputs to determine the amount of assist required. Steering angle sensors, torque sensors and vehicle speed sensors contribute information to the steering module, which controls the amount of assist required under different driving conditions. Some of these sensors are already common aftermarket replacement items, and the category will continue to grow as more and more vehicles are equipped with EAPS. The newest of these technologies is referred to as “steer by wire,” because under normal driving conditions, there is no physical connection between the steering wheel and the rack and pinion! (It may sound like sci-fi, but this technology has been used in the aerospace industry for years.)

We can also look forward to faster steering response than conventional hydraulic systems, and steering will be almost infinitely adjustable via software updates. The electric motors are long-wearing and quiet, eliminating the squeals and groans common to hydraulic systems. These features make them an ideal choice for luxury cars as well as those quiet-running hybrids. There will be many significant benefits of EAPS for manufacturers, repair shops and vehicle owners, but for those of us behind the counter, one of the best benefits is related to core handling. That fully electric rack and pinion core you just took back contains no fluid to leak all over our floors, counters and uniforms!