This video is sponsored by MAHLE.

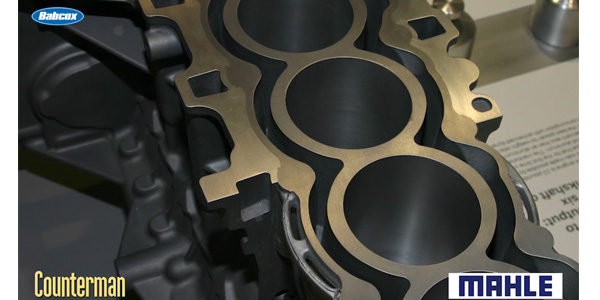

When a head gasket fails, it can create a major headache for your customer. So why would a head gasket fail?

Let’s talk about a couple common reasons for head-gasket failure. One of them is engine overheating. If the engine gets too hot, the cylinder head can swell to the point that it crushes the head gasket, so it no longer seals like it’s supposed to. When this occurs, it provides a leak path for coolant and/or combustion gases, and that’s a recipe for engine damage.

Combustion problems also can cause head-gasket failure. Detonation, pre-ignition or knock all trigger a sharp spike in combustion-chamber pressure, and over time, this can overload and crack the gasket that surrounds the cylinder. This leads to burn-through and loss of compression.

The type of coolant is another possible cause of head-gasket failure. If the vehicle owner has been fighting a leak by topping off the coolant with water or the wrong coolant, it can degrade the head gasket and other gaskets that come in contact with the coolant. Using a conventional green coolant when the cooling system requires organic acid technology or hybrid organic acid technology is another no-no that can degrade the head gasket.

Regardless of why a head gasket has failed, you should recommend a replacement gasket that offers OE form, fit and function. And it’s always a good idea to recommend a gasket set rather than selling individual parts for a repair job, and the appropriate sealer if required. Also, remember that this job requires the bolts to be tightened to the proper specification, so your customer will need to rent or purchase the correct torque wrench.