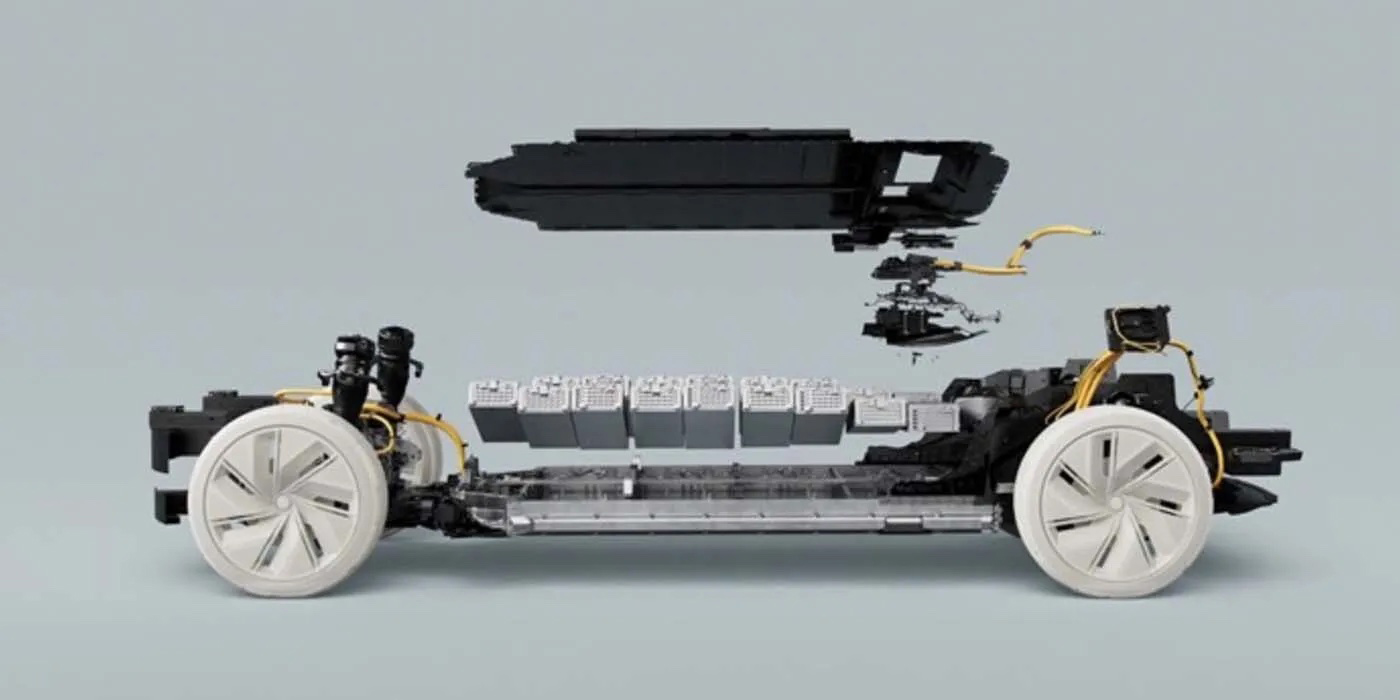

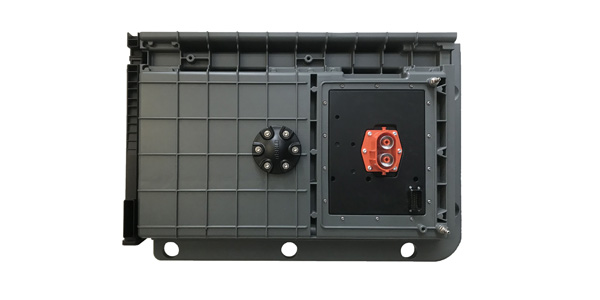

A key factor in the acceptance of electric vehicles is sufficient cruising range. Instead of achieving this by using ever larger batteries, MAHLE offers a newly developed battery housing with integrated thermal management as a solution for increasing the rapid charging capability of the battery.

This allows traction batteries to be about 40% smaller and thus recharged very quickly, according to the company.

“MAHLE is thereby not only reducing the CO2 footprint of the electric vehicle, but also lowering the demand for raw materials for battery production, which are becoming increasingly scarce worldwide,” the company said in a news release.

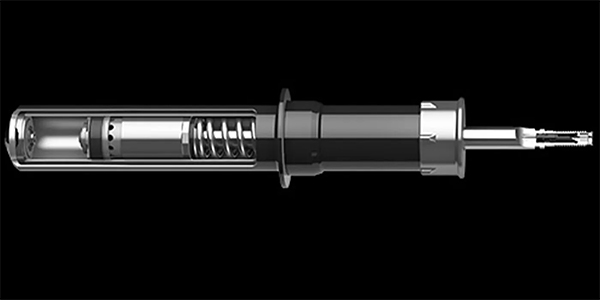

To implement the required high cooling performance during the rapid charging process, the battery cells are surrounded by dielectric fluid as part of the MAHLE battery housing concept. The fiber-reinforced plastic design provides massive weight benefits in the vehicle due to the smaller battery, according to MAHLE.

“With our new battery housing concept, we are making electric vehicles more economical and environmentally friendly – while remaining just as attractive to customers,” said Otmar Scharrer, head of corporate research and advanced engineering at MAHLE. “Both its moderate production costs and the elimination of expensive, powerful batteries are making a targeted contribution to bringing affordable electric vehicles to a broader market.”

The need to cool batteries and power electronics gives rise to complex circuits that substantially increase the requirements on individual components and thermal management control systems. MAHLE has supported the growing electrification of the powertrain and the associated tougher requirements right from the start and is continuously expanding its expertise in research and development.