Here in Northeast Ohio, we recently experienced a “cold snap.” Temperatures dropped below zero degrees Fahrenheit, with wind chills approaching minus 20 F. Needless to say, most people were caught off-guard by the temperatures, and how long that cold weather stuck around.

It highlighted just how much we’re affected by our climate, and for that matter, our cars and trucks. Drivers lost control on highways and had to be towed out of the ditch along the highway, while others weren’t able to start their engine thanks to a weakened battery. I remember many things from my time behind the parts counter, but none more so than this: With each new season comes a pattern of vehicle repairs or needs. You’ll never sell more wiper blades than on a rainy day, and you’ll sell more batteries when temperatures climb or drop to extreme levels. Today, I want to focus on diesel engines and the challenges they face during the winter months.

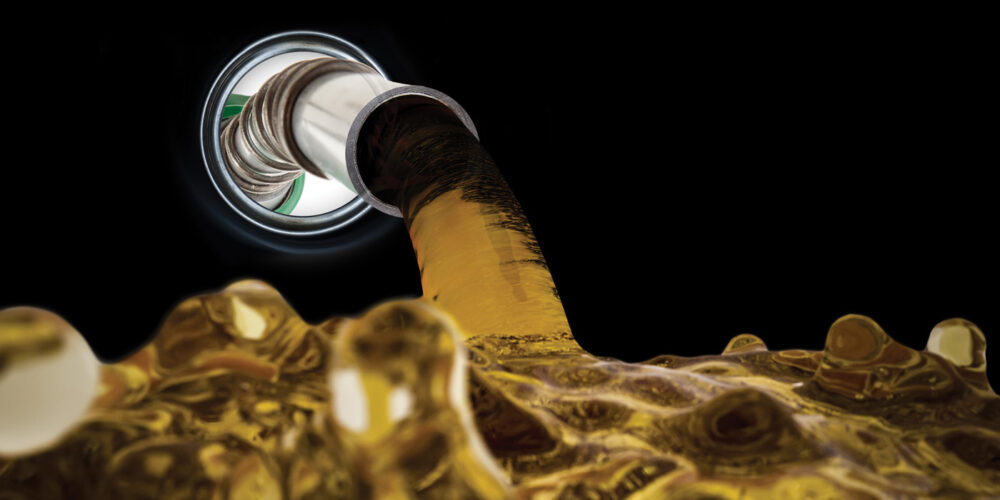

Diesel engines typically are associated with larger pickups, thanks in part to their workhorse nature and their abundant torque production. But cold weather is rather harsh on diesel fuel and the fuel system. When temperatures dip, it can form into a gel instead of a liquid. Cold diesel fuel is harder to ignite under compression, which means the engine has to crank longer than usual. In extreme cold, the engine might become difficult to start even when the glow plugs are given the time to do their job.

Diesel fuel has changed quite a bit in recent decades. The United States has mandated the use of ultra-low-sulfur diesel (ULSD) fuel in an effort to improve air quality. But this also has brought about some chemical changes in the refining process, and with it, some new challenges to overcome. Those chemical changes have caused an increase in paraffin inside the fuel, which can lead to a buildup of wax particles. Those wax particles can form larger crystals that can clog up fuel lines, filters and so on.

Condensation inside the fuel also is a concern. Condensation is a major contributor to rust, cold-weather icing and microorganism growth in warmer weather. Diesel engines can operate much better when corrosion and bacteria growth are prevented.

The Solution: Fuel Additives

Additives aren’t new. In fact, they’re present inside each and every container of oil you carry in your store. When it comes to diesel-fuel additives, they have a simple job to do: Help the diesel fuel to resist the effects of the cold weather. Fuel treatments help to reduce fuel gelling by encapsulating and dispersing those waxy crystals as they’re formed. When done right, this can prevent them from growing large enough to clog any of the components in the fuel system. The fuel is then able to flow more easily through the fuel filters and lines and into the combustion chamber where it can be burned.

Some fuel treatments will contain some or all of the following additives. Lubricity additives help to protect diesel-fuel systems from internal wear. Lubricity additives help the fuel to form a boundary layer of lubrication between the metallic parts inside the fuel system. This film helps to reduce friction between the metal surfaces, and the wear and tear on them. This can extend the life of those components and reduce downtime in the future. Cetane boosters increase the flammability of the diesel fuel, and this allows for a cleaner-burning diesel engine.

What Should You Tell Your Customers?

To most customers, fuel treatments can be thought of as just another routine maintenance item. Most fuel treatments will need to be poured into the fuel tank at each fill-up, but it’s best practice to always reference the usage guidelines from the manufacturer.

If you need help to overcome a cost objection, I wouldn’t suggest trying to scare them with the cost of potential breakdowns or repairs down the road. In my eyes, fuel treatments are simply a “peace-of-mind” sort of sale. Their job is simple, and their objectives are clear. So, if we place ourselves into the customer’s shoes, the benefit they have to offer is the peace of mind that their diesel engine will continue to operate without issue throughout the colder winter months. While it’s true that they can reduce the risk of costly repairs or breakdowns later on, I wouldn’t lead with that thought.

The need for diesel-fuel treatment products will definitely spike as the temperatures start to dip. So, I would invite you to take a few moments to read the labels on the products you carry in your store, and familiarize yourself with what separates one from the next. Then, you’ll be ready to help your customers find the right product for their diesel-powered vehicle.