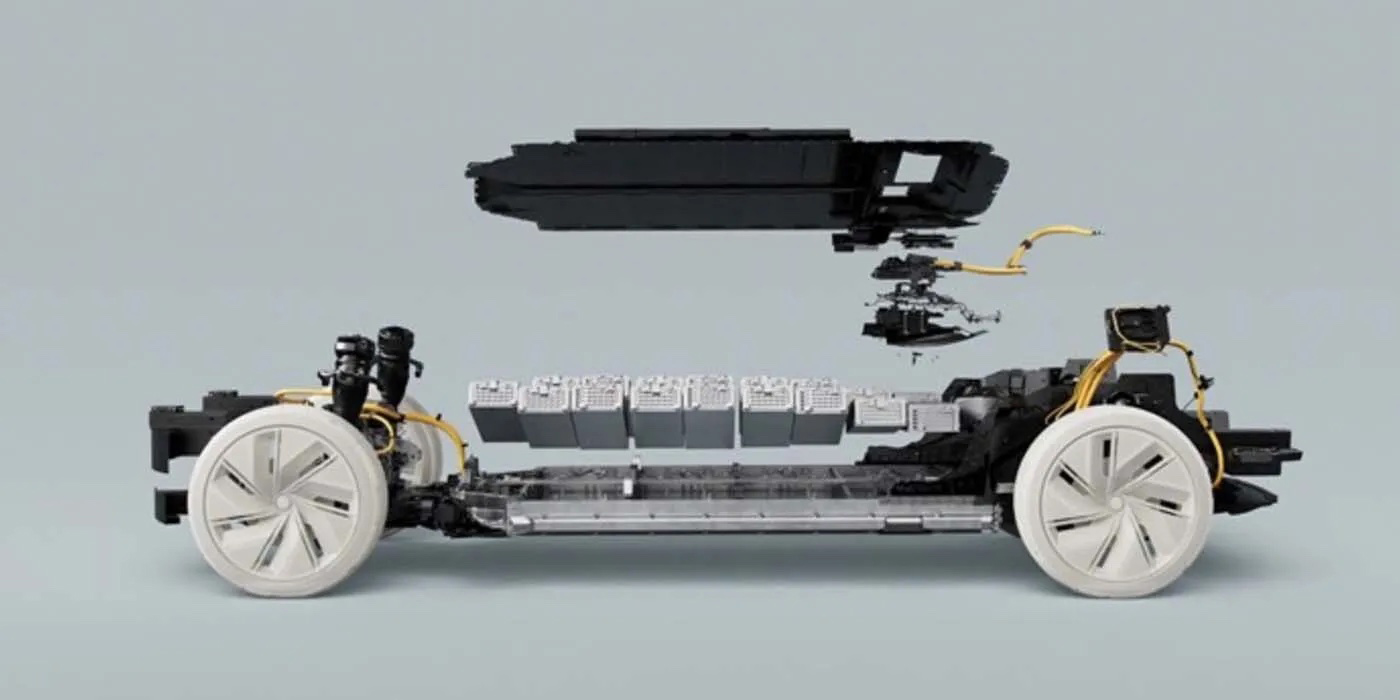

Toyota Motor North America recently announced that it will invest nearly $50 million to construct a new laboratory facility at its North American R&D headquarters in York Township, Michigan, to evaluate batteries for electric and electrified vehicles in North America.

As part of its evaluation process, the new Michigan battery lab will ensure that Toyota’s batteries meet North American customer requirements by confirming performance, quality and durability of automotive batteries made by Toyota.

Operations at the new battery lab are expected to begin in 2025.

“This new investment in our North American R&D operation, which has been a key pillar of the Michigan automotive industry for more than 50 years, shows Toyota’s directional shift towards electrification for all,” said Shinichi Yasui, executive vice president of Toyota Motor North America, research and development. “By adding these critical evaluation capabilities around automotive batteries, our team is positioned to better serve the needs of our customers, including Toyota Battery Manufacturing North Carolina and Toyota Motor Manufacturing Kentucky, the latter of which will soon be assembling the recently announced all-new, three-row, battery electric SUV.”

The team also will work with other North American partner suppliers to incorporate locally-produced battery parts and materials in support of Toyota’s multi-pathway approach to reducing carbon emissions through its portfolio of hybrid, plug-in hybrid, fuel-cell and battery electric product offerings.

Beyond battery development, other lab activities are expected to include evaluations using Level 2 and Level 3 charging as well as connectivity to power sources and infrastructure. Further, chassis dynamometers at both Toyota R&D campuses in York Township and Ann Arbor are being upgraded to accommodate full battery-electric vehicle evaluations.

“With increasing production for electrification coming to North America, it’s important to have local supporting infrastructure, but more importantly it enables us to invest in team members and technology development,” said Jordan Choby, group vice president of Powertrain at TMNA R&D. “This new facility also enables us to experiment and pursue new opportunities as technology and business needs advance.”

In addition to working with current battery production, lab engineers will explore new battery configurations for future products. Their research also may contribute to Toyota’s development of new electrified-vehicle architectures. Toyota will explore further expansion of the lab’s capabilities and opportunities for supporting the needs of the battery and BEV ecosystem.

The new facility will be included in Toyota’s enrollment in DTE Energy’s MIGreenPower program. The voluntary renewable-energy program enables all of Toyota’s Research and Development operations in Michigan to attribute 100% of its electricity use to renewable-energy projects starting in 2026.

Toyota has put more than 23 million hybrids, plug-in hybrids, fuel cell electric and battery electric vehicles on the road globally. The company currently offers 22 electrified-vehicle options in the United States across the Toyota and Lexus brands. By 2025, the company plans to have an electrified option available for every Toyota and Lexus model globally.

Over the last two years, the company has invested more than $8 billion in its U.S. manufacturing operations primarily to support its product electrification efforts. On a global scale, Toyota said it plans to invest more than $70 billion in vehicle electrification by 2030.