TROY, Mich. – Delphi has announced the launch of its MAF sensor (AF10142) covering nearly 5 million GM applications from 2005 to 2011.

Contamination is a key reason why MAF sensors fail and require replacement. As air, dirt and other debris get into the sensor, the parts become contaminated and result in failure. Drivers often notice sluggish performance or a more frequent need to refuel.

Contamination is a key reason why MAF sensors fail and require replacement. As air, dirt and other debris get into the sensor, the parts become contaminated and result in failure. Drivers often notice sluggish performance or a more frequent need to refuel.

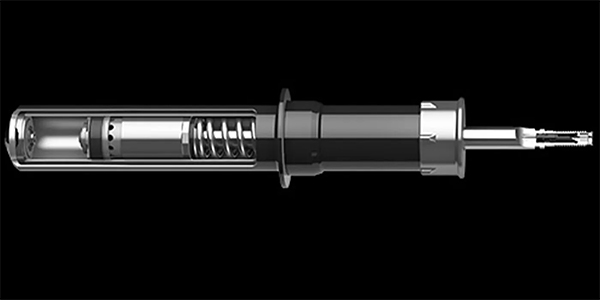

Delphi MAF sensors are built with all-new components, not remanufactured parts. All parts are tested and calibrated to OE standards using OE equipment in U.S. facilities, the company states. By testing to OE specifications, Delphi says it helps ensure the sensors provide accurate readings and airflow output, which helps to reduce comebacks.

And when a Delphi MAF sensor is used in combination with Delphi oxygen sensors, the engine’s air/fuel ratio can be controlled much more accurately, according to the company. All of these functions ensure accurate air/fuel ratio for optimal engine performance.

In addition, Delphi’s unique design eliminates the need for an additional flow tube, the company says. Eliminating the flow-tube helps shops reduce inventory, shelf space and eliminate the hassle of remanufactured cores. Shops also receive Delphi Mass airflow sensors in a plastic clamshell, which helps protect the sensing elements from damage.

Inventory is available now. Visit go.delphi.com for specific part information.