Turbos are back. The automakers are under the gun to raise their fleet-wide Corporate Average Fuel Economy (CAFE) numbers to 40.3 to 41.0 mpg by 2021, and 48.7 to 49.7 mpg by 2025. One of the ways this is being accomplished is to downsize engines and add a turbocharger so vehicles can achieve better fuel economy with no sacrifice in performance.

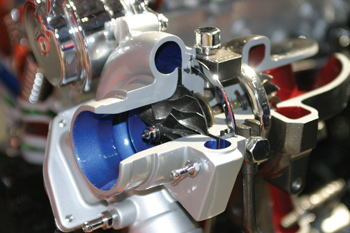

Hanging a turbo on a small engine allows a little engine to breathe big. With only 6 to 8 pounds of boost pressure, a turbo can increase power output 15 to 25 percent or more over a naturally aspirated engine. Consequently, a turbo four-cylinder engine be used in place of a larger V6, and a turbo V6 can replace a larger V8 with no loss of performance.

Hanging a turbo on a small engine allows a little engine to breathe big. With only 6 to 8 pounds of boost pressure, a turbo can increase power output 15 to 25 percent or more over a naturally aspirated engine. Consequently, a turbo four-cylinder engine be used in place of a larger V6, and a turbo V6 can replace a larger V8 with no loss of performance.

The only time an engine really needs the extra power is when it is accelerating hard or pulling a load. A turbo is perfect for this kind of application because it is exhaust-driven and draws no power from the engine like a belt-driven supercharger. Superchargers can deliver right-now boost at low RPM, but the trade-off is a constant drain on the engine when the extra boost pressure isn’t needed. A turbo, on the other hand, is just along for the ride and doesn’t develop any boost pressure until the throttle opens and exhaust flow increases. It then spools up and starts pushing more air into the engine. Turbos can rev up to 140,000 to 160,000 RPM or higher, but it can take a few seconds to reach these speeds. Because of this, engineers design the turbo system so it can reach maximum boost pressure with minimum lag.

Proper sizing of the turbo is essential to reduce lag. A smaller turbo will spool up more quickly at low engine speeds than a large turbo, but a large turbo can flow more air and develop more boost pressure and power. Since the emphasis now is more on fuel economy than all-out performance, most of the new passenger car turbo engines are equipped with relatively small turbos that deliver just enough boost to offset the smaller displacement of the engine.

Boost pressure is controlled by a device called a “wastegate.” The wastegate valve opens a bypass circuit that controls how quickly boost pressure builds. It also limits peak boost pressure so the engine doesn’t go into detonation. Too much boost pressure can destroy an engine that isn’t designed to handle it. The operation of the wastegate is controlled by the Powertrain Control Module (PCM), so it is possible to tweak the turbo’s output by reprogramming the PCM. An aftermarket “tuner” scan tool can load new programming that turns up the boost pressure for more power. These have been a popular item for turbo diesel engines in pickup trucks, but recently General Motors said it will not honor any engine or drivetrain warranty claims on trucks that have been modified with a performance tuner.

One thing all turbos need to survive is good lubrication and cooling. Synthetic oils are best for turbos because they can handle higher operating temperatures. Regular oil and filter changes are also essential to prevent viscosity breakdown, varnish deposits and sludge that could damage the turbo.