Delphi Product & Service Solutions has announced the addition of 23 new ignition coils to its engine management product portfolio, covering more than 7.3 million vehicles, including Audi, Chevrolet, Dodge, Hyundai, Ford, Honda and Jeep applications from 1991 to 2013. Part numbers include: GN10234, GN10396, GN10397, GN10398, GN10415, GN10416, GN10417, GN10418, GN10420, GN10422, GN10425, GN10426, GN10435, GN10443, GN10444, GN10446, GN10448, GN10451, GN10455, GN10457, GN10458, GN10507 and GN10509.

Why Ignition Coils Fail

Why Ignition Coils Fail

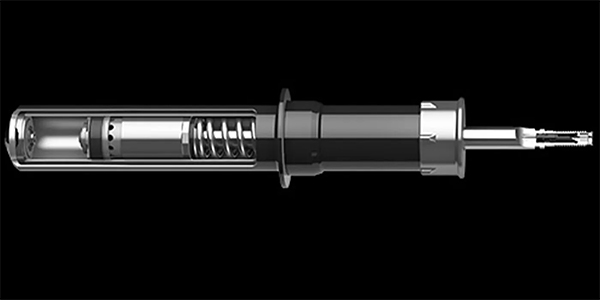

Ignition coils operate in a tough environment. Stresses created by vibration, temperature changes and even the failure of spark plugs and other components can cause ignition coil wiring to break or short out. The insulation inside the ignition coil also can fail, causing energy to escape.

Delphi offers three reasons to choose its ignition coil line:

1. Precision Manufacturing Processes

Delphi backs up its ignition coil design with intelligent manufacturing. The company uses winding process techniques to control the length of wire between adjacent windings. That’s important because more length results in greater voltage differences, which can create more pressure that could break down the insulation and wire coating, the company says.

2. Tested and Proven with the Delphi Difference

Built with the benefit of more than 100 years of OE heritage, Delphi ignition coils are engineered to OE specifications. Delphi coils are designed and endurance-tested to resist the common stresses that cause failure.

3. Innovative Design and Materials

Delphi has analyzed the environment that ignition coils must withstand and is combating failure issues with high-quality design and materials. The company backs its ignition coil design with proven materials, such as high quality wires and wire coating that resists the cracks, pin holes and imperfections that most often lead to failure issues. Delphi also uses an epoxy vacuum technique to reduce air bubbles in the epoxy, because having fewer air bubbles increases the epoxy’s insulating quality and reduces the chances of energy punch-through failures.

Visit go.delphi.com for specific part information.

Tool Intel – Understanding Air Tool Fittings and Couplers

Why don’t air tools come with fittings installed? Here’s why customers need to buy what they actually need.

Your customers may be using air tools in a variety of circumstances for an even wider variety of jobs. Here's how to help them understand why they need to buy the right fitting for the application.

View Full Diagram Here

There are multiple different sizes and styles, and what one shop uses may not be the same as another. The size and style affect the volume of air they can deliver, a critical point because air tools require a specific pressure and volume for proper operation, and restrictive fittings can limit their performance. Here’s a look at the most common sizes and styles found in most automotive shops, and how you can identify them.

Read the April Digital Edition of Counterman

The April issue contains article designed for technical training, management efficiency and store profitability.

ASE Education Foundation Seeking Outstanding Instructor

Nominations are being accepted for the 2024 Byrl Shoemaker/ASE Education Foundation Instructor of the Year award.

Why Does Engine Coolant Need Replacement?

Two specifications can be used to justify replacement — the condition of the additive package & the freezing point.

Gaskets vs. Seals

Whether your customer asks for a gasket or a seal, you know one thing: They’re trying to stop a leak.

Other Posts

LITESTIX Work Light by BendPak Now Lasts Longer

Larger battery keeps rechargeable hands-free light shining bright for up to seven hours.

Lisle 61860 Oil Filter Housing Torque Adapter

Prevent over-tightening of plastic and aluminum oil filter canisters and filters.

ZF Expands SACHS CDC Shock Line for U.S., Canada

The release reflects growing demand for advanced damping technology in the aftermarket, company says.

Customer Service: How It’s Done

Customer service should be your number one priority, and it all starts with the greeting.