A vehicle’s ability to stop quickly, safely and quietly depends on the condition of its brake pads. The pads create friction when the brakes are applied, converting the kinetic energy of motion into heat.

Most of the heat is dissipated through the brake rotors, but the pads also get hot. A hard panic stop or riding the brakes continually while mountain driving can raise brake pad temperatures several hundred degrees. And, the hotter the pads get, the faster they wear.

There are no recommended replacement intervals for brake pads because pad life varies widely depending on how a vehicle is driven, the type of brake pads on the vehicle, the driver’s braking habits and even the design of the brake system.

Frequent stop-and-go city driving in heavy traffic may wear out a set of pads in as little as 30,000 to 40,000 miles – or even faster depending on how aggressively the driver uses their brakes. On the other hand, a set of brake pads on a vehicle that is driven mostly on the highway may last upwards of 70,000 to 80,000 miles or more.

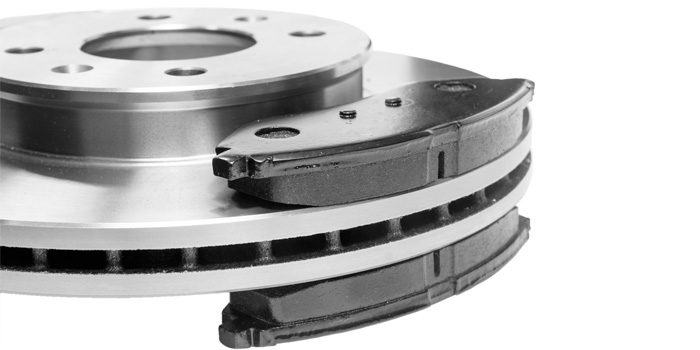

Regardless of how a vehicle is driven, all brake pads eventually wear out and have to be replaced. When pads are worn down to minimum thickness specifications (usually around 1/8th inch), they should be replaced.

Driving on thin pads can be dangerous because there is a risk the friction material may crack, separate or delaminate from the steel backing plate. The only way to know how worn a set of brake pads are is to measure their thickness. Brake pads should be inspected when tires are rotated, if they are making noise, or if the brakes are pulling, grabbing or braking unevenly. Brake pads also should be replaced if the disc brake calipers are leaking fluid and fluid has gotten on the pads.

Pads also can be contaminated by grease leaking from an outer constant velocity joint or a leaky wheel bearing seal. Brake pads should usually be replaced in sets (both front, both rears or all four). Traditionally, front brake pads wear two times to three times faster than rear pads or shoes, so often only the front pads need to be replaced.

However, in recent years many vehicles have shifted more of the braking force to the rear wheels to reduce overall stopping distances. Consequently, the rear brakes may wear at the same rate as the ones in the front, or even faster. Replacement brake pads come in various materials (ceramic, nonasbestos organic (NAO), low metallic and semi-metallic). Some even have different friction materials for the inner and outer brake pads. Brake pads also in various price/quality grades (good, better or best). Premium-quality replacement pads cost more but usually provide the best overall value for the money.

Premium pads use superior materials and construction and will usually brake quieter, wear longer and brake better than standard or economy grade replacement pads. Upgrading brake performance by replacing standard pads with premium pads often can eliminate noise problems, brake dust problems, wear problems and even high-temperature fade problems with some original equipment pads.

The OEM brake pads on many European luxury cars provide good, high-speed stopping power but are notoriously dirty, leaving ugly black brake dust on the wheels. The relatively soft OEM brake pads on some Asian makes provide quiet braking, but wear out relatively quickly. Switching to a premium-quality aftermarket friction material that is engineered specifically for these kinds of applications can overcome the shortcomings of some OEM friction materials and improve driver satisfaction.

Other items a customer may need when changing brake pads include rotors, brake fluid, calipers, brake hoses, steel brake lines, brake service tools and/or rear drum brake hardware and shoes.