NUCAP announced a new partnership with leading retailer Canadian Tire to offer its flagship NRS galvanized brake pads.

“We are proud to partner with Canadian Tire and increase availability of NRS galvanized steel brakes, the longest-lasting brake pads available today,” said Montu Khokhar, CEO of NUCAP. “As an innovation company, NUCAP has developed solutions across the global brake and automotive sectors, as well as in the technologies that power them, with an emphasis on creating best-in-class products that improve the quality of people’s lives.”

NRS galvanized brake pads, designed and manufactured in Toronto, were created to provide long-term reliability and safety for all cars in which they are installed. Because NRS Brakes are made from galvanized steel, rust or delamination will never happen, according to the company.

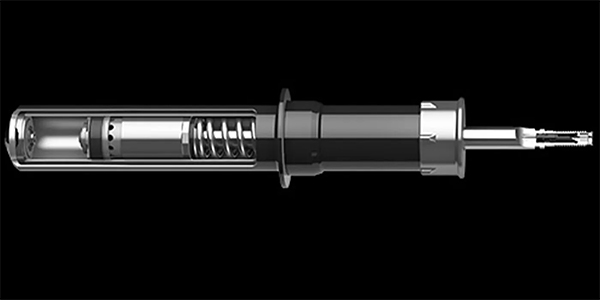

Tested to the breaking point, NRS’s friction was designed to exceed OEM standards. Its exclusive patented NRS technology mechanically fuses the backing plate to the friction material, creating an indestructible bond. The result is a more reliable, long-lasting and safer brake product, according to the company.

“Summer is the perfect time to tackle those long-overdue projects like replacing your brakes and upgrading to rust-resistant, long-lasting NRS galvanized brake pads,” said Zack Zeraldo, category business manager for Brakes at Canadian Tire. “NRS galvanized brake pads can be ordered online through www.canadiantire.ca and DIYers can install the pads themselves, or take them to a Canadian Tire Auto Service Centre for quick, expert installation. We always encourage drivers to stay on top of brake maintenance and choose top-quality replacement parts, like these NRS pads, to ensure safety for themselves and others on the road.”

NRS galvanized brake pads come with noise-cancelling piston insert technology. The custom-fitted, elastomer-coated ring insert fits precisely into any open caliper piston, significantly reducing noisy stops caused by vibration or excessive heat that can occur with traditional brake pads.

“Canadian drivers demand a powerful and durable product; galvanized brake pads are the only option when it comes to safe brake performance and longevity year-round,” Khokhar said. “For over 25 years, NUCAP has been producing top-quality brake pads designed and manufactured in Canada for the leading global OE and aftermarket companies. Over the course of over two decades, our company has been developing new technologies as well, such as our GripMetal and SpiderTech product lines, suited for a wide range of applications and industries.”