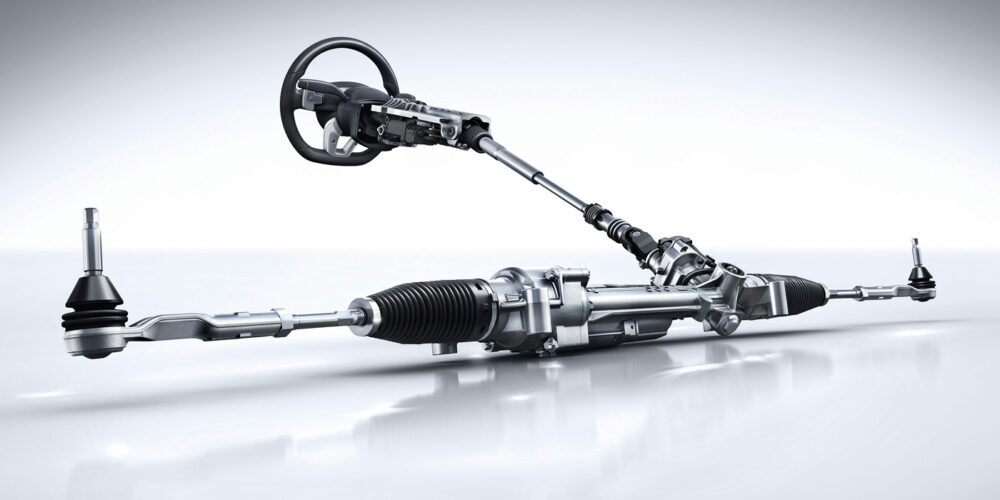

Rack-and-pinion steering is the predominant type of steering system on vehicles today.

Simplicity is one of the reasons for their popularity. On these systems, an inner and outer tie-rod end on each side connects the steering rack to the steering knuckle. The inner tie-rod ends tend to last longer than the outers because they have a smaller range of motion, and they simply don’t get the same abuse as the outers on these systems.

Throughout the life of a vehicle with rack-and-pinion steering, it’s not uncommon to replace outer tie-rod ends multiple times, and rarely or never replace the inners – as long as the boot (also known as bellows) that protects them from dirt and moisture isn’t damaged.

Before rack-and-pinion steering became popular, a parallelogram steering linkage was the predominant setup on most cars and trucks, consisting of a pitman arm, idler arm, center link and inner and outer tie-rod ends on each side. The tie rods are connected by a tie-rod sleeve. Even after rack-and-pinion systems became popular and virtually standard on all cars, parallelogram steering remained in use on trucks, vans and heavy-duty vehicles for many years, but today rack-and-pinion is becoming more common on them too.

There’s another type of steering system you may run across, also common on some trucks and heavy-duty vehicles, and it consists of a drag link and tie rods. The difference is there’s no idler arm. A drag link goes from the pitman arm to a tie rod that connects to the steering knuckle, and second tie rod runs from the first to the other steering knuckle.

Terminology can vary, but don’t let that throw you. In this illustration, No. 4 is the drag link, No. 2 and No. 1 are tie rods. Some people may refer to the drag link as an inner and outer tie rod. Also note No. 6, a steering damper, is a common feature on heavy-duty vehicles.

When selling steering components, it can be useful to look at a diagram, in case your customer is unsure of the name of the component they need. You also can use it as an aid in pointing out additional items they may need.

The Quality Question

It’s not uncommon to be asked about quality, especially with the different lines and varying cost of the steering components you sell. The “economy” or “value” line is designed to make it affordable to repair a vehicle. There’s nothing wrong with these components. I’ve used them many times, and they’re as safe as any other. Will they last as long? Most likely not, but many people choose to go this way because it’s simply all they can afford, and we all can respect that.

On heavy-duty or vehicles that the owner plans to keep long-term, it’s best to recommend a higher-end line of components. They’ll last longer, and you also can remind your customer that every time you replace a steering component, an alignment must be performed. That’s an additional cost, and worn components also will cause abnormal tire wear. A less expensive component that doesn’t last as long actually might cost more in the long run.

Where’s the Grease Fitting?

Fewer steering components come with grease fittings than in the past. Many people perceive this as a sign of “cheap” or low quality. This is far from the case. Many high-quality steering components today are constructed with better materials and higher-quality lubricants. Lack of a grease fitting doesn’t mean low quality. But it does mean there’s no way a poor-quality lubricant can be added to the joint, it can’t be over-greased, and there’s no way for moisture or contaminants to find their way in either.

Here’s the kicker: Is your customer going to personally grease the fittings themselves? As a professional technician, if I had a nickel for every greaseable joint I’ve seen that was completely worn out, with not even a remote sign of grease ever having touched the zerk fitting … you know the rest. This is reality. Blame it on whomever. If the greaseable joints aren’t going to be greased, I’d rather have those not designed for it.

Extras

There are a few good suggestions to keep in mind when selling steering components. If it’s a rack-and-pinion vehicle, rack boots are a good suggestion since the outer tie-rod ends must be removed to replace them. On parallelogram steering, when tie rods are replaced, tie-rod adjusting sleeves are a huge benefit. These are almost always rusted in place and difficult to loosen and turn. New sleeves make the installation much quicker, as well as the alignment. If the vehicle has a steering damper, it’s always a great recommendation. These tend to get ignored, but are commonly worn out. And finally, don’t forget grease for the grease gun, and shop rags to clean up the mess.