Most older vehicles have disc brakes in the front and drum brakes in the rear. Many newer vehicles have four wheel disc brakes. Disc brakes generally provide greater stopping power than drum brakes.

The most common wear components in the brake system are the brake pads, rotors, shoes and drums. The front brake pads typically wear at a higher rate (2x to 3X) than the rear shoes or pads. But in some late model European and domestic vehicles with electronic brake proportioning, the rear brakes do more work and may wear as fast or even faster than the front pads. Pad life may range from 30,000 miles up to 60,000 miles or more depending on the type of driving, vehicle weight, the braking habits of the driver, and the type of pads used. Semi-metallic pads and ceramic pads

The most common wear components in the brake system are the brake pads, rotors, shoes and drums. The front brake pads typically wear at a higher rate (2x to 3X) than the rear shoes or pads. But in some late model European and domestic vehicles with electronic brake proportioning, the rear brakes do more work and may wear as fast or even faster than the front pads. Pad life may range from 30,000 miles up to 60,000 miles or more depending on the type of driving, vehicle weight, the braking habits of the driver, and the type of pads used. Semi-metallic pads and ceramic pads

typically provide longer service life than softer nonasbestos organic (NAO) pads.

Worn pads should always be replaced with ones that are the same or better friction material. Ceramic pads are often recommended as an upgrade for NAO pads because they provide longer life, quiet braking and produce little or not visible dust. Semi-metallic pads are usually required for high-temperature, high-load applications.

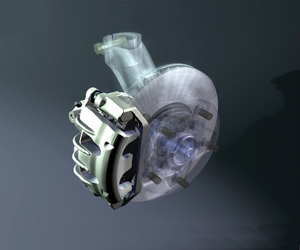

When linings are replaced, the rotors and drums may need to be resurfaced or replaced depending on their condition. If a rotor is worn to minimum thickness, or a drum is worn to maximum diameter, replacement is necessary. Most rotors are made of cast iron, but “composite” rotors have a thin stamped steel center hat attached to a cast iron rotor ring.

Composite rotors are more difficult to resurface and more prone to pedal pulsation problems than one-piece cast rotors. They are also more expensive than cast. Composite rotors can be replaced with cast rotors as long as both rotors are replaced at the same time (don’t intermix different kinds of rotors side-to-side).

Most front rotors are vented, while most rear rotors are not, because more cooling is usually needed for the harder-working front brakes. Most rotors are interchangeable left to right, but some are directional so pay close attention to the catalog listings when looking up part numbers. New rotors are ready to install and do not require additional resurfacing (turning rotors unnecessarily shortens their service life).

Other wear components in the brake system include the calipers, wheel cylinders and master cylinder. Corrosion inside the piston bores, and/or seal wear can cause these components to leak. If the piston(s) in a caliper are sticking due to corrosion, the result can be reduced braking effectiveness, brake drag, and/or uneven pad wear. A caliper with sticking pistons should be replaced. New caliper bushings and mounting hardware are also recommended, and the caliper slides should be lubricated with high temperature brake grease to assure proper operation.

For drum brake service, new springs and mounting hardware are recommended when the shoes are replaced. Corrosion and heat can damage hardware, increasing the risk of brake drag and noise. Wheel cylinders should be replaced or rebuilt if leaking or sticking. New wheel cylinders are required if the bores in the old wheel cylinders are pitted, worn or rough.

Most vehicles have power brakes provided by a vacuum booster mounted on the firewall behind the master cylinder. The booster uses engine vacuum to multiply braking force. Some vehicles use hydraulic pressure generated by the power steering pump or the antilock brake system pump to provide power assisted braking. Failure of the booster or pump can cause a loss of power assist. On ABS systems, the fault may be electrical rather than mechanical, such as a bad ABS pump motor relay.

Brake fluid carries the hydraulic pressure created in the master cylinder through the brake lines to the front calipers and rear calipers or drums to apply the brakes. Brake fluid also wears out over time and should be replaced when the brakes are serviced. The main issue here is moisture contamination that causes a breakdown of corrosion inhibitors in the fluid and lowers the fluid’s boiling temperature (which increases the risk of fluid boil and pedal fade under hard use). DOT 3 and DOT 4 brake fluid are the two main types and both are glycol-based hydraulic fluids. DOT 5 fluid is a silicone-based fluid and is used only for special applications (like older vehicles that sit for long periods of time or are operated in extremely wet environments). DOT 4 has a higher temperature rating than DOT 3, and is used in many European vehicles. Use the type of fluid specified by the vehicle manufacturer.

Rubber brake hoses can also deteriorate with age and leak. Any hose that is cracked, bulging, leaking or damaged should be replaced without delay because of the danger of brake failure should the hose leak. Steel brake lines can corrode internally or externally. Replacement brake lines must be steel with double-flared or ISO end fittings.

Related items that may also need to be replaced when servicing the brakes include the wheel bearings and seals. On older vehicles with serviceable wheel bearings, the grease seals should always be replaced when the bearings are cleaned and repacked with grease. Special high-temperature wheel bearing grease is required (never ordinary chassis grease).