This winter, extreme weather patterns have been disrupting daily routines nationwide. Flooding, snowfall and subzero temperatures all have taken a toll on our roadways and vehicles, leaving many stranded or unable to leave their homes. For those who can make it out to the streets, driving conditions can be hazardous. Having a reliable, fully charged battery is critical during these weather events.

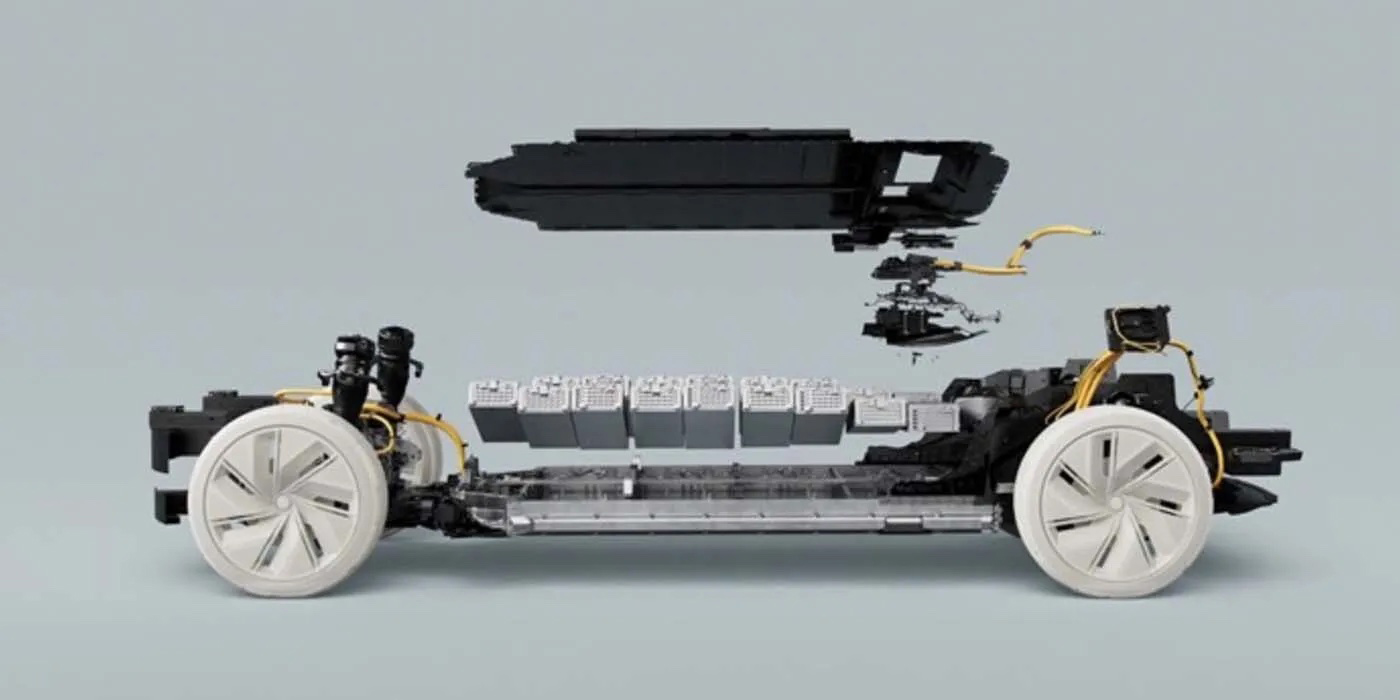

Several news reports lately have highlighted the negative effects of extreme weather on the growing segment of electric vehicles (EVs). Just as the lead-acid batteries found in conventional automobiles suffer during cold snaps, the battery packs found in EV and hybrid vehicles endure a similar kind of stress. As temperatures drop to freezing and below, EV efficiency (measured in miles per kilowatt-hour, or m/kWh) can be reduced by as much as 34%, shortening effective range. Unfortunately for EV owners, the reduction in range brought about by these cold temperatures means more frequent charging events.

As temperatures plunge, these charging events can take even longer. EV batteries need to achieve a minimum internal temperature before accepting a charge, so the vehicle prioritizes battery preheating before it begins the actual charging process, which itself is less efficient at low temperatures. These delays can lead to lines at public charging stations, and increased numbers of immobile EVs stranded roadside when batteries go flat before reaching a charging station.

Our customers with EVs still have the same type of 12-volt auxiliary battery commonly found in ICE-powered vehicles featuring stop-start technology. The BCI groups 400 and LN1 are just two of the popular AGM applications in this category. For ESS or hybrid vehicles, this battery is necessary for powering accessories when the engine is off, while EVs need a 12-volt power source isolated from their high-voltage traction systems. Maintenance-free AGM batteries are most often used in these applications, due to their ability to recharge quickly and a longer service life when compared to other types of lead-acid batteries.

Lithium-ion batteries (like those used in cordless tools around the shop) are becoming a popular auxiliary option for EVs as well as ICE-powered vehicles. Lithium-ion batteries have a higher energy density than their lead-acid counterparts, so they can pack the same amount of power into a smaller (and lighter) case. Tesla has been using lithium-ion technology for its auxiliary battery in the Model 3, S, X and Y since 2021.

Intelligent Battery Sensors

As batteries and charging systems become more advanced, use of an intelligent battery sensor (IBS) is becoming more commonplace. BMW has used battery sensors since 2002, and uniquely requires “registration” to notify the PCM that a new battery has been installed. This update allows the PCM to tailor the battery-management system to the output of the new battery. The sensor now has a reset “baseline” to make decisions on charging voltage, idle speed and other parameters that affect drivability and battery life. In addition to measuring current in and out of the battery, the IBS also may monitor battery state of charge, state of health and even temperature.

No matter if you’re daily-driving an ICE or an EV, a properly maintained battery and charging system is critical to reliable starting in all kinds of weather. Fortunately, given today’s battery technologies, it’s even easier to maintain and monitor these systems than ever before!