The name “power booster” is a bit misleading. A power booster doesn’t add more horsepower, nor does it unleash a lightning-sized shot of nitrous oxide into the intake manifold. Instead, a power booster gives the brake system superpowers – allowing a grandmother on the way to church to stop as quickly as Arnold Schwarzenegger on the way to his helicopter.

How can this be, you say? Through the magic of power-assisted braking, of course.

There are three common types of power brake boosters in use today. Hydro-boost is frequently found on diesel vehicles and uses the power-steering system to operate. Electrohydraulic systems are commonly seen in hybrid cars that don’t produce enough vacuum for a traditional power booster. Vacuum brake boosters are the most common type of power brake system, found on the majority of late-model vehicles.

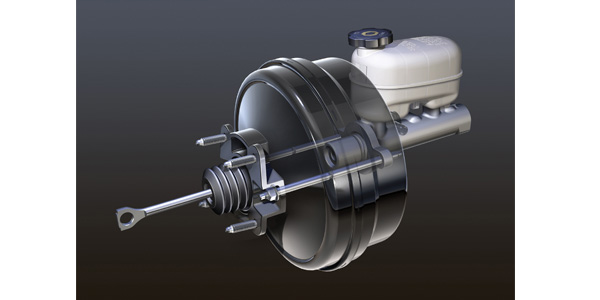

Vacuum-assisted brake boosters multiply the amount of force exerted by the driver to the brake pedal. Vacuum brake boosters typically are mounted between the brake pedal and the master cylinder, using intake-manifold vacuum to increase the pedal force when applying the brakes.

The brake-booster housing contains a rubber diaphragm inside a large, hollow shell. An air valve opens when the brakes are applied, allowing atmospheric-pressure air to enter the supply side of the booster. The diaphragm moves toward the side with engine vacuum when the valve is open. This movement, along with the driver input on the brake pedal, pushes on the master cylinder instead of using force directly from the driver’s foot. If no vacuum is present or the valve does not open, the brake pedal will be difficult to push.

A one-way vacuum check valve from the engine to the booster pulls atmospheric air from the vehicle into the booster. If the check valve leaks, it may allow oil residue to flow to the diaphragm and cause it to fail eventually. If the brake pedal requires more effort to stop and hold at a light, it may be a sign of potential failure.

The amount of power assist that a vacuum booster provides depends on the vacuum supplied and the size of the booster diaphragm. The larger the diaphragm, the greater the brake assist. In general, larger vehicles require more brake assist as well as a bigger booster than smaller cars.

Most vacuum boosters will last the life of the car if there are no issues. But one of the things that does fail is the check valve, which reduces the power part of the assist. And if any fluid gets into the diaphragm of the booster – whether from the master cylinder or check valve – it can cause the rubber to fail. A new master cylinder and booster will be needed if this happens. And fluid around the back of the master cylinder would be another indication of a probable leak.

Most often, brake-booster problems are due to a plugged or leaking vacuum hose. The restriction in the line slows down the vacuum return, or vice versa. The booster may fail to hold sufficient vacuum if the check valve is leaking, making the brake pedal harder to push. Since engine vacuum is the key to making the brake booster function, anything that impedes this function also will affect the brakes if it’s severe enough.