Thanks to the science of hydraulics, we don’t have to stop our cars like Fred Flintstone on his way to Ed’s Mammoth Ribs Drive-Thru. Late-model hydraulic master cylinders are divided into two separate circuits, with each having its fluid reservoir and piston. Dual master cylinders are a safety feature added in the late 1960s. Two separate systems mean at least two brakes are functional enough to stop the vehicle if one fails.

On most vehicles, the hydraulic system is split diagonally. The left front and right rear brakes are linked to one circuit, and the right front and left rear brakes are linked to the other.

The most common master-cylinder failures occur from piston-bore wear and piston-seal failure. The classic symptom of a failing master cylinder is a brake pedal that “dives” or sinks slowly to the floor while pedal pressure is being applied. Another sign to look out for is any leaks around the master cylinder. If a seal is worn out, it may leak past the seal and onto the pushrod that attaches to the brake pedal. Also, look for any lines that connect to the cylinder for leaks. If the leak is internal from one of the seals, then the master cylinder should be replaced, but external leaks may require a line or fitting to be replaced.

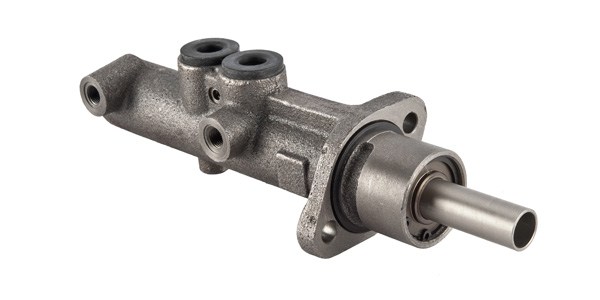

Most master cylinders consist of a housing, reservoir, piston, rubber cup, return spring and a rubber boot. A cylinder bore is machined into the center of the housing. The spring, cup and piston(s) slide in this bore and produce hydraulic pressure. The reservoir keeps the system full of fluid as the brake lining wears and the dust boot serves to prevent contaminants from entering the rear of the master cylinder. Since the master cylinder works like a foot-operated pump, it pushes brake fluid through steel lines and out to the pistons on the calipers or wheel cylinders to apply braking pressure on the rotor.

On vehicles equipped with a power brake booster, a vacuum leak can allow fluid to leak past the pushrod seal. It’s recommended that the booster and master cylinder be replaced if this situation occurs.

Another issue that can crop up on some vehicles is using the wrong type of brake fluid. Some seals are sensitive to the type of brake fluid used in the system. Be sure to replace fluid with the kind that’s recommended by the manufacturer and bleed the system. Some seals can twist in the retention groove and create a small leak (i.e., Acura/Honda). The brake fluid then can leak into the brake booster, and the brake light eventually will come on because the brake-fluid level is low. There are master-cylinder repair kits available for some applications that come with new seals and pistons.

When a customer complains of a brake problem, be sure to ask if the brake pedal dives and if there are any noticeable leaks around the floor or brake booster. It’s also a good idea to check the brake fluid and make sure it’s not corroded. Old, dark brake fluid can cause corrosion and should be replaced with the correct fluid type, so you don’t have to resort to the Flintstones’ braking method.