Brake calipers are a commonly replaced component on high-mileage disc brake systems. As time and miles add up, calipers experience wear and corrosion – especially aluminum and steel caliper pistons, which may cause a piston to stick and the brake to drag. Caliper piston bores can become corroded, worn and pitted, which can also contribute to piston sticking and fluid leaks. Leaky piston seals can allow a dangerous loss of brake fluid, which can contaminate the brake pads and may even result in brake failure.

The caliper casting itself is made of cast iron or aluminum and is fairly rugged. Even so, some calipers may develop wear or even cracks where it rides on its slides or bushings. The calipers should always be carefully inspected when the brake pads are replaced, and most professional technicians recommend replacing high-mileage calipers even if they are not leaking or sticking to restore like-new brake performance.

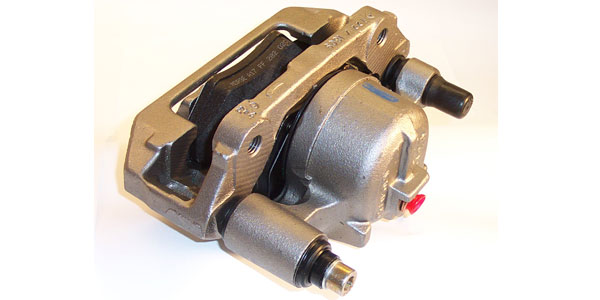

Replacement options include new or remanufactured calipers, “loaded” calipers (complete with new pads and hardware), and “semi-loaded” calipers (no pads but hardware included).

Which is best? It depends how your customer defines what’s best for their situation. A new caliper is a brand new casting that has never been on the road. As such, it has experienced no corrosion or wear. If the new casting is from a supplier that can match OEM quality, it should fit and function exactly the same as the original equipment caliper it replaces. The only drawback is cost. New calipers typically cost more than reman calipers.

However, all new calipers are not the same. A low-cost offshore supplier may cut corners in the quality of the alloy used in the casting, or the dimensional accuracy of the casting (particularly the bore size) may be off slightly, which may lead to leaks or piston sticking down the road. Substituting cheaper piston materials may also jeopardize the long term durability of the caliper. Caliper pistons have to be precisely manufactured to exact size specifications and use OE-equivalent materials (steel, aluminum or phenolic) so thermal expansion (and swelling due to moisture absorption in the case of phenolic pistons) does not cause the pistons to stick. If a low cost supplier doesn’t pay close attention to these kind of details, their calipers may cause trouble down the road.

Reman calipers can also vary in quality depending on their price and who does the remanufacturing. One caliper remanufacturer said it rejects many castings because of their condition or appearance. They also do not reuse any steel pistons when they rebuild a caliper. They only use brand new pistons — and 100 percent pressure test every caliper to make sure it is leak free before it goes in the box. Some low-cost remanufacturers will salvage as much of the old caliper as they can to minimize cost, and may use lesser quality piston seals and dust boots to keep their prices low. A cheap caliper can provide a cheap fix for some customers, but it likely won’t be a long term fix. Better to recommend a quality caliper backed by a warranty. Many reman calipers are sold on an exchange basis so the remanufacturer can have an ongoing supply of rebuildable cores. However, to get full core credit the old core must be complete (no missing parts) and rebuildable. Core credit may be deducted for castings that are cracked, badly worn or severe corroded. Many fully loaded floating calipers are sold complete with the mounting bracket, so the core that is turned in should likewise include the bracket. As a rule, calipers should be replaced in pairs (both fronts, both rears, or all four). New brake hoses will likely be needed also, along with fresh brake fluid. All brake lines must also be bled to remove air after the calipers have been installed. If not bled properly, the vehicle may end up with a soft spongy brake pedal or no pedal at all.