Developed together with a strategic partner in the backing plate manufacturing industry, this new product represents the potential for a total weight-savings of up to 7.5 kilograms per vehicle (combination of truck and trailer), according to TMD.

LUXEMBOURG/LEVERKUSEN – Plans for the introduction of more stringent CO2 emission limits present a real challenge for the automotive parts industry. Research and development experts are continually called upon to design and develop lightweight solutions to support the reduction of fuel consumption through decreasing vehicle weight. Now, TMD Friction has developed what it believes to be a first for the brake friction industry to address these challenges.

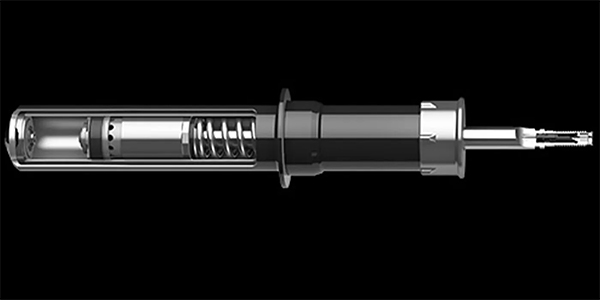

The latest addition to the “TMD Friction Light Technology” family is a new lightweight brake pad for commercial vehicles is exclusively available from TMD Friction. Developed together with a strategic partner in the backing plate manufacturing industry, this new product represents the potential for a total weight-savings of up to 7.5 kilograms per vehicle (combination of truck and trailer), according to TMD.

TMD says the product reduces component wear on the axle and brake system due to the reduced “unsprung mass” and reduced CO2 emissions. Alternatively, a higher payload can be achieved, the company says.

As a safety-critical component, the brake pad plays a very important role in the everyday safe operation of both heavy and light vehicles. The braking power required to decelerate a vehicle is several times greater than the actual engine power output. For example, when a fully loaded 40-ton truck brakes from 80 km/h to a standstill, the brakes convert energy corresponding to approximately 3,650 HP. To achieve weight reduction in safety critical components while meeting such high mechanical and thermal loads represents a very significant challenge for development engineers.

At TMD Friction, development engineers have been able to meet this challenge by designing a unique mechanical connection between friction material and backing plate. In the lightweight pad development the reduced thickness of the optimized stamped steel plate is compensated for by a thicker connective material layer, resulting in a pad with unchanged total thickness and no fitment compatibility issues.