WHEELING, Ill. – Penray has introduced a new line of heavy-duty coolant filters featuring synthetic media with what it calls “triple-layer engineering.”

The new Penray synthetic media coolant filters are designed to last up to 150,000 miles, 15 months or 3,000 operating hours, and are fully compatible with conventional coolants as well as new-generation Extended Life Coolants (ELCs). They are available for all popular Class 6, 7, and 8 vehicles, as well as for many mobile off-highway and marine applications. Penray also offers synthetic media filters for use with Extended Life Coolants (ELCs).

The new Penray synthetic media coolant filters are designed to last up to 150,000 miles, 15 months or 3,000 operating hours, and are fully compatible with conventional coolants as well as new-generation Extended Life Coolants (ELCs). They are available for all popular Class 6, 7, and 8 vehicles, as well as for many mobile off-highway and marine applications. Penray also offers synthetic media filters for use with Extended Life Coolants (ELCs).

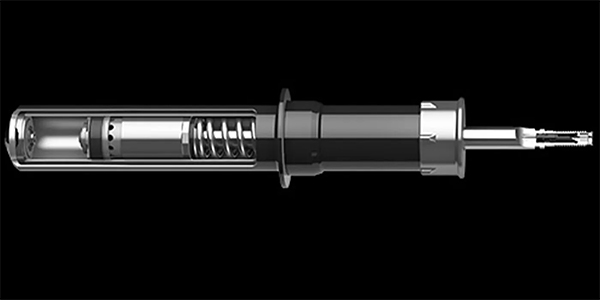

According to Penray, the key to the effectiveness and durability of these new heavy-duty coolant filters is the company’s fiberglass-based filtering media incorporated into a sophisticated triple-layer design that provides exceptional filtration, even in extreme operating conditions. Penray says the design is built on a structural steel screen with an epoxy coating that provides a durable foundation, which is wrapped in a non-woven sheet of polyester. All of this is encased in Penray’s new fiberglass filtration media. The triple-layer construction allows these new filters to achieve unusually high levels of filtering efficiency and capacity for up to 150,000 miles, according to Penray.

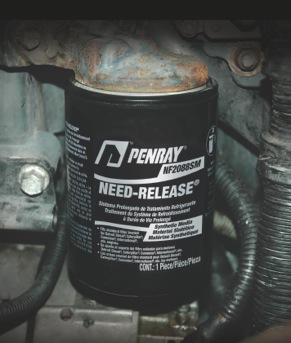

In addition to the synthetic media, many of these new filters incorporate Penray’s exclusive “Need-Release” technology, which the company says introduces coolant additives and fortifiers on an as-needed basis, stabilizing the coolant for optimum effectiveness. Unlike time-release filters, which distribute additives at fixed time intervals even when not needed, Penray’s Need-Release filters include a membrane that senses deterioration in the coolant chemistry, and responds by releasing one of its four charges of additives and fortifiers to restore coolant chemistry. Over time, as key components of the coolant are depleted, the Need-Release technology releases additional charges of supplements to again restore the coolant to viability. This process continues over extended periods of time until all four charges have been released.

Penray also offers mounting brackets, plates and hardware for retrofit, as well as threaded bushing adapters, which will allow fleet maintenance personnel to assure that all vehicles in the fleet use the same coolant filter, which can greatly reduce inventory requirements, the company says.

“The introduction of these new synthetic media coolant filters assures superior filtration for the long service intervals that are becoming common in heavy-duty fleet maintenance,” said Sarah Cooper, product manager for Penray. “This new construction is the perfect complement to our time-tested Need-Release technology, which meters supplements and fortifiers on an as-needed basis rather than on a fixed and often ineffective time-based interval as is the case with other designs. The smart technology of our Need-Release chemistry assures that a vehicle’s coolant will maintain the proper efficacy for an extended period of time and use, minimizing down time and maintenance costs and enhancing vehicle productivity.”

Information on Penray’s filter products can be found at www.penray.com/powerfleet.