Brakes are one of the best-selling product lines in any parts store. As a safety and inspection item, there is great demand for brake parts from your service dealer customers, and many DIY customers are comfortable tackling these repairs at home, too. To accommodate the various customer needs for price, quality and performance, it is common to stock several different lines of brake pads. In our store, we have six stocking lines of brake pads (with others available for special order!), and three grades of brake shoes. Customers of all types are very conscious of their choice in friction materials, but are somewhat less concerned with the quality of their rotors and drums. Most are content to purchase the “store brand” rotor, based on the lower price or in-store availability. While some customers still specify a premium quality disc or drum, economy brands account for an overwhelmingly large percentage of rotor and drum sales, and the inventory turns can be staggering on popular numbers.

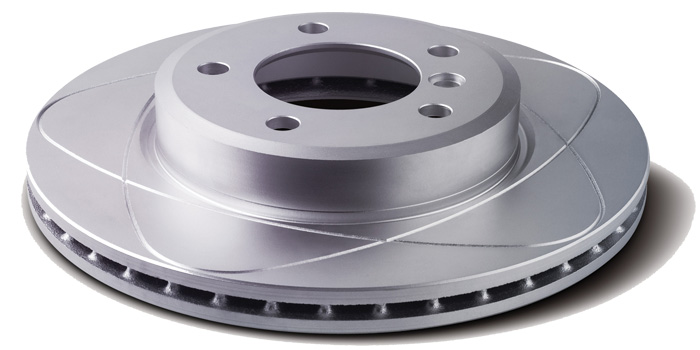

I believe that most “economy” rotors are manufactured to a price point rather than a quality standard. The supplier is contracted to provide a product, machined to acceptable tolerances, and in large quantities. In order to maintain large volume production at such low prices, these tolerances may not be as exacting as those required by a premium supplier. The cast iron used in the manufacturing process may not have the same quality as an OEM or premium product, and the casting itself may be lighter in mass. Comparing two rotors of different brand/quality, you may discover there is a significant difference in weight, as well as in their design and finish. For vented rotors, a common way to “save weight” is in the finned air gap around the rotor’s edge. The rotors’ overall thickness may be the same, but the amount of material used may be significantly different. Thinner castings leave less material for heat transfer, and may contribute to runout, vibration or brake noise. It also may make it more difficult to machine the rotor in the future. Rotors and drums are stamped with “machine to” and “discard” measurements, to indicate the minimum safe operating dimensions as specified by the OE manufacturer. These specifications also may be found in your electronic or paper cataloging. If your store offers brake lathe services, there is likely a policy against machining drums and rotors that are close to or below these specifications. Machining a thin-casting rotor, even if the finished product is still within these specs, can result in inferior performance.

A common complaint with rotors is “warping,” even though it is more correctly referred to as “disc thickness variation” (DTV). Rotors do not warp like a CD left on the dashboard in July, but they do experience uneven wear patterns, caused by a number of conditions. One of the most common is improper wheel torque. Every manufacturer has torque specifications for installing lugnuts (or studs, for many European cars), and recommends a torque sequence or pattern to achieve even clamping force. Overtorquing or unevenly torquing lugnuts can contribute to DTV, and should be avoided. Lateral runout is another condition that is often described as “warping.” Runout is the side-to-side motion or “wobble” of the rotor as it turns, and even a few thousandths of an inch of runout can cause pedal pulsation, which a customer may describe as a “warped” rotor. Improper lugnut torque, loose or worn wheel bearings and dirty or corroded mounting flanges can cause runout, which leads to DTV as the pads and rotors wear unevenly against each other. While a customer may occasionally encounter a truly defective rotor or drum, repeated complaints of “warping,” (especially from the same customer, or repeat failures on the same vehicle) may be indicative of improper installation practices, or other component failures. Addressing these issues can be tricky, because it must be handled delicately to avoid insulting the customer or questioning their skill. This is especially true of your professional customers. Blaming the product will only hurt your own reputation, and blaming the customer is sure to drive away business.

Recommending premium-quality components and encouraging proper installation can increase sales, and decrease your warranty returns. The vehicle owner will benefit from a better, longer-lasting product and professional technicians will get fewer customer complaints, comebacks and labor claims. Taking the time to properly diagnose problems and perform the repair correctly is the mark of a professional service provider, but it is up to you as a parts specialist to help supply them with the products and services they need to succeed.