We deal with a LOT of electrical components on a daily basis, but equally important is the wiring that connects these components to the rest of their circuits. Sensors, switches, solenoids and actuators require electrical power to do their jobs. Quite often, though, our customers condemn the part we just sold them as “defective” when it doesn’t fix their issue.

Considering the thousands of feet of wire in today’s automobiles, along with dozens of quick connectors and repair pigtails, sometimes it’s just a matter of bad wiring that causes our quality parts to look bad. Repairing these wires and connections requires only a handful of basic tools and some universal supplies, many of which we sell and stock every day.

Electrical troubleshooting can be intimidating to the novice, and sometimes frustrating even for the professional. At its most basic level, all we really need is power at the correct voltage, and a ground to complete the circuit. Diagnostic tools of all kinds use basic electrical principles to help us find and isolate the problem. From the most advanced digital volt ohm meter (DVOM), right down to a homemade continuity tester made from wires and a light bulb, you’re looking for the potential to pass electricity through a circuit.

The DVOM, also known as a “multimeter,” combines many of these tests into one handheld unit. It can test for continuity, resistance, voltage and amperage, giving the user the ability to diagnose issues in powered or un-powered circuits. Specialized attachments can test spark plug wires, fuse blocks and even probe temperatures.

The simple “ice-pick” continuity tester is sort of a “go/no-go” gauge to show if there is a break in a powered circuit. If a completed circuit is ON, it lights up. No lights? No power! The self-powered test light is similar to the continuity tester, but has its own power source, so it can be used on components that are disconnected from their circuit. These can be used to actuate solenoids and switches, and power other circuits for component testing.

Once the problem in the circuit has been diagnosed, we must repair the fault in the circuit. If a standalone component is bad, we simply replace it with the appropriate cataloged part. If the fault is in the wiring or a connector, other tools and supplies will be required. For connector failures, technicians often simply connect a new pigtail to the existing wire ends, taking note of the position of each wire and its color coding. For wire failures, the technician would repair or replace the damaged section of wire.

These wiring repairs can be done in many different ways, with varying results and quality.

The most common type of wire repair is a “crimp” connection. A repair terminal or connector is attached to the wire end by stripping away approximately a half-inch of insulation, sliding the terminal over the bared wire and crimping it into place with a plier-type crimping tool. This is only a mechanical connection, and aside from twisting wires together by hand (NOT recommended, by the way!), this is the weakest and least effective type of wiring repair.

The best method of inline wire repair is to twist the wires together and solder the joint, creating a conductive and solid connection that lasts much longer than crimp-type connections. This method requires additional tools and supplies: a soldering iron, rosin-core solder and heat-shrink tubing to insulate the soldered joint. An “in-between” alternative is the heat-shrink crimp connector, which is crimped in place, then heated to create a weather-resistant seal. A quality electrical tape can be used to protect crimped or soldered repairs, but heat-shrink provides better protection. Heat-shrinking can be achieved with a heat gun, or (carefully) with a disposable lighter or mini-torch.

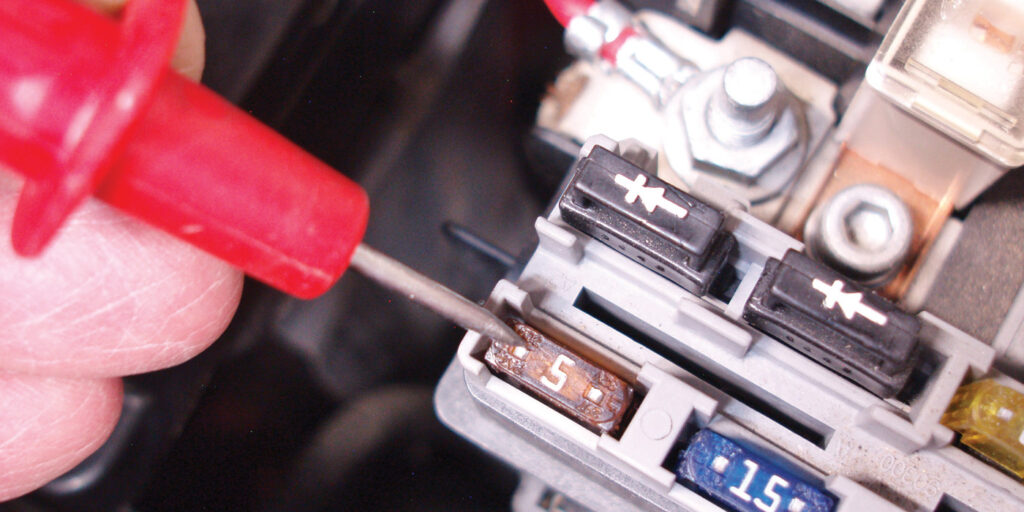

In addition to the most common diagnostic and hand tools, there are a wide array of specialty tools available for various wiring-repair tasks. Some of these are gimmicky, single-purpose tools, but others can be incredibly handy, like terminal-release tools. These special probes are used to release individual wire terminals from their connector housings, although small picks or screwdrivers can work in a pinch. These tools also are helpful for separating connectors from their mating components. Test leads, with pins or alligator clips, also are handy additions to the electrical toolkit, as well as a good variety of repair terminals, wire, tape and fuses.

Most of these tools and supplies fall into the category of “non-catalog” parts, although pigtail connectors usually are found alongside the components to which they connect. Depending on the skill level of the individual customer, you may find yourself recommending one or more of these tools and repair supplies. Knowing these best practices, as well as what tools and supplies are necessary for a particular repair, allows us to recommend the most appropriate solutions, even if it isn’t the component your customer came in for originally!